In the world of construction and manufacturing, the role of Steel Stockists is vital. Henry Clarke, an industry expert, emphasizes, "The right steel stockist can make or break a project." With a wide range of materials available, selecting a reliable stockist becomes essential for success.

Steel stockists serve various industries, supplying everything from beams to sheets. Their connections with manufacturers often determine price and availability. However, not all stockists are created equal. Some may prioritize quick gains over quality service. This inconsistency can leave businesses stranded when they fail to deliver on time.

As companies navigate this landscape, the challenge lies in identifying the best stockists. It’s crucial to understand the market and the key players. Each stockist has unique strengths, but also flaws that could lead to setbacks. The need for thorough research and thoughtful selection is more important than ever in this competitive environment.

The steel stockist industry plays a critical role in the global supply chain. These companies specialize in holding and distributing various types of steel. They serve industries such as construction, automotive, and manufacturing. Steel stockists ensure timely delivery and availability of essential materials. Their networks can be vast, yet efficiency varies widely.

One challenge facing the industry is fluctuation in raw material prices. These shifts can impact stock levels and profit margins. Companies must adapt swiftly. Some stockists invest in technology to track inventory and demand more accurately. Others lag behind, struggling to keep pace. The reliance on traditional methods may hinder growth and responsiveness.

Quality control is another concern. Not all stockists ensure the same standards. This inconsistency can lead to issues in construction projects. Issues may arise from subpar material sourcing. Customers are left with the burden of checking quality, which can be a daunting task. It is essential for companies to reflect on their practices and strive for improvement.

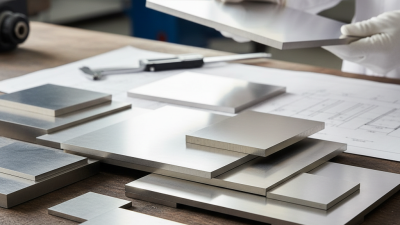

When selecting top steel stockist companies, several important criteria come into play. Product diversity is critical. A stockist should offer various steel grades and sizes. This variety supports different industries and projects. It's essential to ensure that the stockist can meet specific requirements.

Quality assurance is another key factor. Companies should have a system for testing their steel products. Certifications can indicate a commitment to high standards. Yet, not all companies emphasize this part. Transparency about sourcing and production processes is often lacking. This can lead to confusion about product reliability.

Customer service cannot be overlooked. Quick response times and knowledgeable staff make a difference. A stockist should be easy to communicate with. However, some companies fail in this area. Limited communication can frustrate customers and hinder project progress. Look for those who prioritize strong customer relationships. It’s worth considering all these elements when choosing a supplier.

In the competitive world of steel stockists, certain companies stand out due to their unique offerings. Many of them specialize in various grades of steel, addressing diverse industry needs. Their services often include custom cutting, delivery options, and comprehensive inventories. The best stockists ensure that their products meet rigorous quality checks.

One notable observation is that some companies struggle with inventory management. Delays can occur when stock levels are not aligned with demand. This can hinder construction projects and disrupt business operations. Additionally, fluctuating steel prices can impact client trust. Steel stockists must adapt to changing market conditions while maintaining strong relationships with suppliers.

The profiles of these leading companies reveal patterns of excellence and areas for improvement. Most invest heavily in technology to streamline processes. However, reliance on automation can sometimes overlook the human element. Personal relationships and on-the-ground insights are invaluable. A balanced approach can lead to better decision-making and customer satisfaction.

Steel stockists play a vital role in the supply chain. They provide essential services that cater to various industries. One key service is inventory management. Efficient stockists maintain a wide range of steel products. They ensure a steady supply that meets customer needs. Research indicates that stockists hold about 20-30% of the total steel supply in a region.

Another important function is processing services. Many stockists offer cutting, drilling, and shaping services. This saves customers time and reduces waste. In fact, studies show that value-added services can increase a stockist's margins by 15-20%. However, not every company excels in this area. Some struggle with maintaining quality and efficiency.

Logistics solutions are also crucial. Effective transportation is needed to deliver steel promptly. Yet, many stockists face challenges with fleet management. Delays and mishandling can occur. Research suggests that 25% of stockists report issues in this area. This can lead to missed deadlines and dissatisfied clients. It is essential for stockists to continually assess their logistics to improve customer satisfaction.

The steel stocking sector is evolving rapidly. Industry reports indicate that global steel demand may reach 1.9 billion tons by 2025. This growth fuels innovation among stockist companies. They are introducing advanced inventory management systems. These systems reduce excess stock and improve order accuracy.

Sustainability has become a focal point. A significant number of steel stockists are investing in eco-friendly processes. This includes using recycled steel. As the data suggests, recycled steel can save up to 74% of energy compared to producing new steel. Despite these efforts, many companies still face challenges in balancing sustainability and profitability.

Digital transformation is another key trend. Companies are increasingly adopting e-commerce platforms to streamline operations. Yet, not all businesses manage this transition smoothly. Some struggle with user experience and digital integration. Investing in technology is essential, but it’s often met with resistance. The steel industry must navigate these hurdles to fully embrace modernization.