In the construction and manufacturing industries, the selection and installation of fabricated pipes are crucial for efficiency. Fabricated pipes play a significant role in various applications, from plumbing to industrial processes. According to a report by the American Society of Mechanical Engineers (ASME), over 40% of pipe failures are attributed to improper installation and selection.

Choosing the right fabricated pipes involves considering material, size, and system requirements. A wrong decision can lead to increased costs and project delays. For instance, a study from the National Pipe Association indicates that inadequate specifications can result in up to 30% more maintenance needs over the lifespan of the system. This emphasizes the importance of thoughtful selection amid cost pressures.

Yet, the process is not devoid of challenges. Many professionals overlook critical factors, such as environmental conditions and pressure ratings. These oversights can have serious ramifications. The industry must reflect on past experiences to improve future projects. Knowing the importance of detailed planning and execution is essential for success in working with fabricated pipes.

Fabricated pipes are essential in various industries, such as oil and gas, construction, and manufacturing. According to a recent industry report by Research and Markets, the global market for fabricated pipes is projected to reach $15.5 billion by 2025. This growth highlights the significance of understanding the types and applications of these pipes.

There are mainly three types of fabricated pipes: welded, seamless, and threaded. Welded pipes are widely used for high-pressure applications. Seamless pipes, on the other hand, are stronger and ideal for high-temperature environments. Threaded pipes often serve in plumbing and gas applications due to their easy installation. The choice of pipe type impacts project efficiency and safety.

Installation can pose challenges. Proper alignment is crucial; misalignment could lead to leaks. Regular inspections are often neglected, increasing the risk of failures. According to the American Society of Mechanical Engineers (ASME), improper installations affect approximately 20% of piping systems. Choosing the correct fabricating method also requires reflecting on long-term maintenance costs versus initial expenses.

When selecting fabricated pipes, several key factors come into play. The material choice is crucial. Different materials offer various benefits. For example, stainless steel is durable but can be expensive. PVC pipes are lightweight and cost-effective but may not withstand high pressure. Assess your project's specific needs before making a decision.

Consider the operating environment as well. Will the pipes be exposed to extreme temperatures? Or will they be underground? These conditions can impact the material's performance. Test the pipe properties against these conditions for better durability.

**Tip:** It's wise to consult with professionals. Their expertise can save you time and money. They can guide you to the right pipe selection for your unique project.

Installation is another important aspect. Ensure you have the right tools. Using the wrong equipment can lead to mistakes. Misalignment or improper sealing can cause leaks.

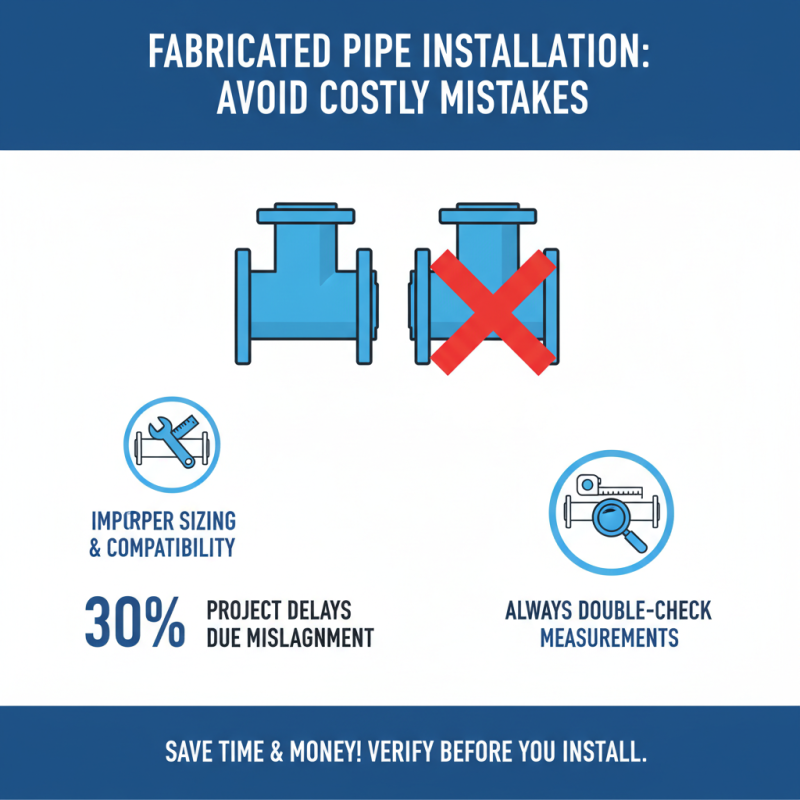

**Tip:** Always double-check measurements before cutting. A small error can lead to significant issues later. Take your time to reflect on your choices during the selection process. Careful consideration now can prevent problems in the future.

| Factor | Description | Material Options | Typical Applications |

|---|---|---|---|

| Material Type | Choose the right material for the intended use, considering factors like corrosion and temperature. | Stainless Steel, PVC, HDPE, Carbon Steel | Water Supply, Oil & Gas, Chemical Processing |

| Pipe Diameter | Select an appropriate diameter to ensure optimal flow and pressure management. | 1 inch, 2 inches, 4 inches, 6 inches | Water Distribution, HVAC Systems |

| Pressure Rating | Ensure the pipe can handle the maximum pressure of the system. | 150 PSI, 300 PSI, 600 PSI | Industrial Applications, Fire Protection Systems |

| Installation Method | Decide on the installation technique based on the project requirements. | Welding, Socket Fusion, Flanging | Construction Projects, Pipeline Systems |

| Cost | Analyze budget constraints and compare costs of different materials and sizes. | Budget-Friendly Options, Premium Quality | Various Applications based on budget |

Installing fabricated pipes can seem daunting. Start by gathering all necessary materials and tools. Ensure you have the right pipe fittings as well. Check the dimensions before cutting any pipes. Accurate measurements avoid costly mistakes.

When it’s time to install, dry-fit the pipes first. This step helps you see how they connect. Adjust as needed. Keep in mind that misalignment can lead to leaks. Use a level to ensure everything is straight. Apply the appropriate sealant where necessary. This is crucial for long-lasting joints.

Once installed, check for any signs of issues. Look for tight connections and proper support. Sometimes, unforeseen challenges arise. Your initial plan may not account for every detail. Be ready to troubleshoot. Always take notes on any adjustments made for future reference.

When installing fabricated pipes, common mistakes can lead to project delays and increased costs. Many installers overlook the importance of proper sizing and compatibility. In a recent industry report, 30% of project delays were attributed to misaligned dimensions. Always double-check measurements before installation. It may seem tedious, but it saves time later.

Another frequent oversight is inadequate cleaning of pipe ends. Contaminants can create weak joints. According to industry guidelines, dirt or grease on pipe surfaces increase failure risks by 20%. Ensure all surfaces are clean and dry to promote a strong seal.

Tip: Use the right connectors for your pipe material. Incompatibility can cause leaks and other failures. Remember, investing time in selecting the right fittings leads to a more reliable installation.

Lastly, many underestimate the importance of pipe support and alignment. Improperly supported pipes can sag or break. In one survey, 25% of respondents experienced sagging issues due to inadequate support. Regular checks during installation can help identify these issues early.

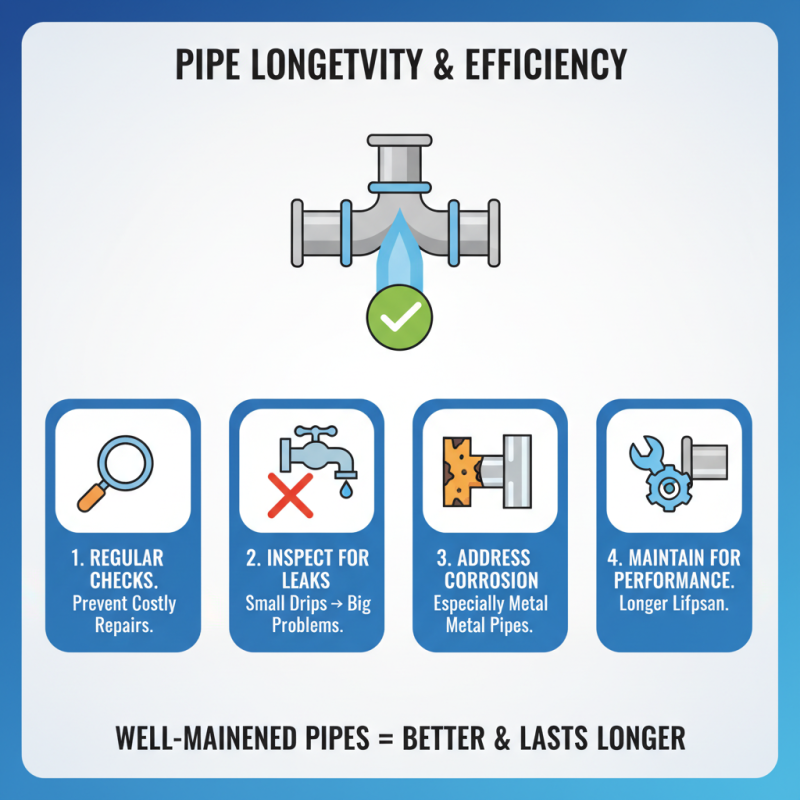

Maintaining fabricated pipes is crucial for their longevity and efficiency. Regular checks can prevent costly repairs. Inspect joints and connections for any signs of wear. Small leaks can turn into big problems if left unattended. Pay attention to corrosion, especially in metal pipes. A well-maintained pipe will perform better and last longer.

Cleaning is essential too. Over time, deposits can build up inside pipes. This buildup restricts flow and can cause pressure issues. Use appropriate cleaning methods suitable for the materials involved. Avoid harsh chemicals that may damage the pipes. Some might underestimate the impact of maintenance. A proactive approach can save both time and money in the long run.

Storage also matters. If pipes are not in use, store them properly. Keep them dry and off the ground to avoid moisture accumulation. A little care during storage can prevent future deterioration. Regular maintenance might seem tedious, but it’s a small price to pay for reliability. Making these small adjustments can greatly enhance the lifespan of your fabricated pipes.