Nickel alloy pipes are crucial components in various industries, recognized for their exceptional resistance to corrosion and high-temperature stability. As experts such as Dr. Emily Thornton, a leading metallurgist in the nickel alloy field, have noted, "The unique properties of nickel alloy pipes make them indispensable in applications where traditional materials fail." This resilience has led to their widespread adoption in sectors ranging from aerospace to chemical processing.

The versatility of nickel alloy pipes is evident in their application in high-stress environments, where they can withstand extreme temperatures and corrosive substances. Industries that require reliable piping solutions are increasingly turning to nickel alloys for their ability to offer long-term performance and reduced maintenance costs. As we explore the top ten applications of nickel alloy pipes, it becomes clear that understanding their role can significantly enhance operational efficiency and safety in critical industrial processes.

Nickel alloy pipes are renowned for their exceptional properties, which make them ideal for various demanding applications across different industries. One of the standout features of nickel alloys is their resistance to corrosion, particularly in environments that are acidic or have high salinity, which is crucial for applications in chemical processing, oil and gas, and marine industries. Additionally, nickel alloys possess excellent mechanical strength and toughness, even at elevated temperatures, allowing them to maintain structural integrity under challenging conditions.

The versatile nature of nickel alloys also facilitates their use in high-performance environments where durability and reliability are essential. Their ability to withstand thermal expansion and maintain stability under stress makes them suitable for heat exchangers, pressure vessels, and pipelines that operate under high thermal and mechanical loads. Moreover, nickel alloy pipes can be fabricated into various shapes and sizes, enhancing their adaptability across applications ranging from aerospace and defense to power generation. The unique combination of strength, corrosion resistance, and thermal stability continues to drive the demand for nickel alloy pipes in specialized industrial sectors.

This chart represents the top applications of nickel alloy pipes, showcasing their unique properties and the industries where they are heavily utilized.

Nickel alloy pipes are indispensable in a variety of industrial applications due to their exceptional corrosion resistance, high strength, and ability to withstand extreme temperatures. In the oil and gas sector, these pipes are extensively used in offshore drilling and refining processes. Their durability ensures that they can endure harsh marine environments and the high pressures associated with deep-sea extraction operations. Additionally, the chemical processing industry relies on nickel alloy pipes for transporting corrosive substances, as these materials can withstand the aggressive chemicals without losing their integrity.

Another significant application of nickel alloy pipes is in the aerospace sector. The high-performance requirements of aircraft engines demand materials that can withstand extreme thermal and mechanical stress. Nickel alloys provide the necessary properties to ensure reliability and performance in these critical components. Furthermore, power generation industries utilize nickel alloy pipes in nuclear reactors and fossil fuel applications, where their resistance to heat and corrosion contributes to the overall efficiency and safety of energy production systems. These varied applications highlight the importance of nickel alloy pipes across multiple sectors, underscoring their role in supporting modern industrial infrastructure.

| Application | Industry | Key Benefits | Common Grades |

|---|---|---|---|

| Oil and Gas | Energy | Corrosion resistance, high strength | Inconel 625, Incoloy 825 |

| Chemical Processing | Chemical | Durability, resistance to acids | Hastelloy C-276, Monel 400 |

| Aerospace | Aerospace | High strength-to-weight ratio | Inconel 718, Inconel 625 |

| Marine Engineering | Marine | Saltwater corrosion resistance | Monel 400, Inconel 925 |

| Power Generation | Energy | Heat and corrosion resistance | Incoloy 800, Hastelloy X |

| Pharmaceuticals | Pharmaceutical | Purity, corrosion resistance | 316L, Hastelloy C-22 |

| Food Processing | Food | Sanitary, corrosion resistance | Monel 500, Inconel 600 |

| Pulp and Paper | Manufacturing | Durability, chemical resistance | Incoloy 825, Hastelloy B-2 |

| Waste Management | Environmental | Corrosion resistance, strength | Inconel 600, Monel K-500 |

| Telecommunications | Technology | Reliability, corrosion resistance | Inconel 625, Incoloy 800HT |

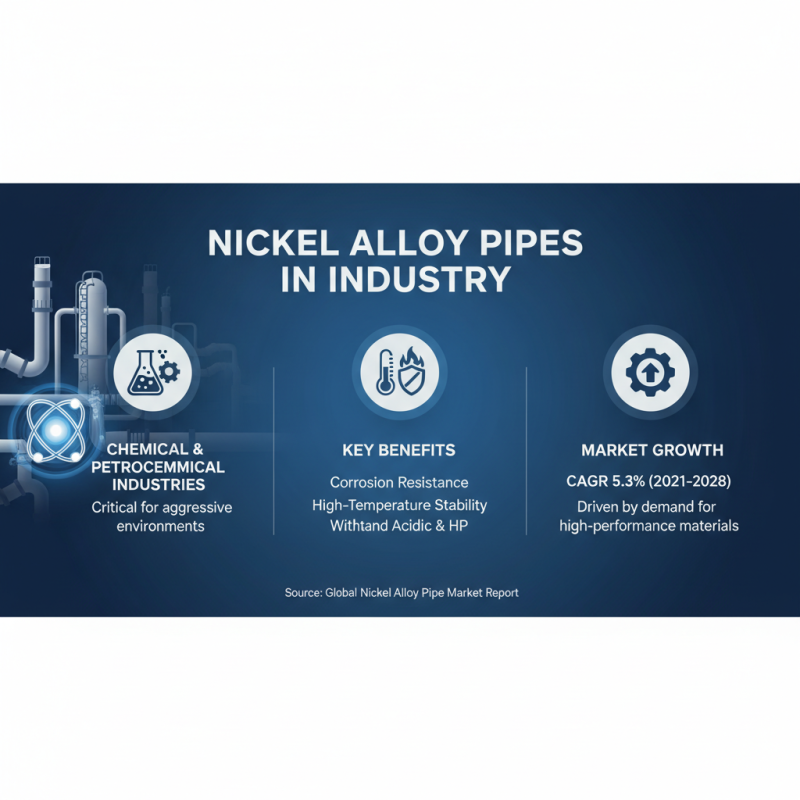

Nickel alloy pipes play a pivotal role in the chemical processing and petrochemical industries, primarily due to their excellent resistance to corrosion and high-temperature stability. According to a report by the Global Nickel Alloy Pipe Market, the use of nickel alloys in these sectors is projected to grow at a CAGR of 5.3% from 2021 to 2028. This growth is fueled by the increasing demand for high-performance materials that can withstand aggressive chemical environments while maintaining structural integrity. Nickel alloys, particularly those containing manganese and chromium, are known for their ability to resist pitting, crevice corrosion, and stress corrosion cracking, making them ideal for applications involving acidic solutions or high-pressure environments.

In chemical processing, nickel alloy pipes are commonly utilized in heat exchangers, pressure vessels, and reactors. The American Society for Testing and Materials (ASTM) suggests that these alloys can endure operating temperatures exceeding 1000°F (about 540°C) and pressures upward of 10,000 psi. Moreover, in petrochemical applications, nickel alloy pipes are increasingly preferred for transporting hydrocarbons and other corrosive substances, given their ability to perform reliably under harsh conditions. Industry experts indicate that between 20% to 25% of all materials used in chemical plants are nickel-based alloys, underscoring their significant role in enhancing safety and efficiency in these demanding applications.

Nickel alloy pipes have become increasingly popular in marine and offshore applications due to their exceptional resistance to corrosion and high temperatures. In environments where saltwater and harsh conditions prevail, these alloys provide a durable solution that minimizes the risk of failures and maintenance costs. Their ability to withstand pitting, crevice corrosion, and stress corrosion cracking makes nickel alloys ideal for various components including piping systems, heat exchangers, and storage tanks within marine vessels and offshore platforms.

Another significant advantage of using nickel alloy pipes is their mechanical properties, which include enhanced strength and toughness at elevated temperatures. This characteristic is particularly valuable in offshore oil and gas drilling operations, where equipment is subjected to extreme conditions. Additionally, the lightweight nature of these alloys contributes to improved efficiency in design and installation, allowing for more streamlined operations without compromising safety or reliability.

As the demand for resilient materials continues to grow in the marine sector, nickel alloy pipes stand out as a critical component for ensuring the longevity and performance of offshore infrastructure.

The future of nickel alloy pipe technology is poised for significant advancements, driven by the increasing demand for materials that can withstand extreme environments and corrosive conditions. As industries such as oil and gas, aerospace, and marine engineering continue to expand, the innovation in nickel alloys becomes crucial. Researchers are focusing on enhancing the mechanical properties and corrosion resistance of these materials, allowing for longer service life and reduced maintenance costs in critical applications. Advances in additive manufacturing and metallurgical processes are enabling the creation of more complex geometries, providing engineers with greater flexibility in design and performance.

Moreover, the shift towards sustainability is influencing the development of nickel alloy pipe technologies. As organizations aim to minimize their environmental footprint, there is a push for recycling initiatives and the use of eco-friendly practices in production. Innovations such as improved surface treatments and coatings are being explored to extend the lifespan of nickel alloy pipes, making them a more sustainable choice. Additionally, the integration of smart technologies, such as IoT sensors, into these systems provides real-time monitoring of performance and condition, further enhancing reliability and safety in various applications. As these trends continue to evolve, the nickel alloy pipe industry is set to embrace a future filled with opportunities and breakthroughs tailored to meet the ever-changing demands of the global market.