Boiler tubes play a critical role in industrial steam generation. A recent report from the American Boiler Manufacturers Association noted that about 50% of boiler failures are linked to tube issues. These failures can lead to costly downtimes and safety concerns. Maintaining boiler tube efficiency is essential for optimal operation.

Many factors contribute to boiler tube degradation. Corrosion, heat stress, and debris accumulation are significant challenges. For instance, studies show that about 30% of boiler tube failures result from external impacts like scaling and fouling. Moreover, regular inspections can prevent up to 60% of these failures. However, not all facilities prioritize this ongoing maintenance.

Incorporating a robust maintenance strategy improves boiler tube longevity. Data indicates that proactive measures can increase the lifespan of tubes by up to 40%. Facilities often overlook minor repairs. This neglect can escalate into major issues, resulting in expensive failures. A focus on meticulous maintenance is vital for efficient boiler operations.

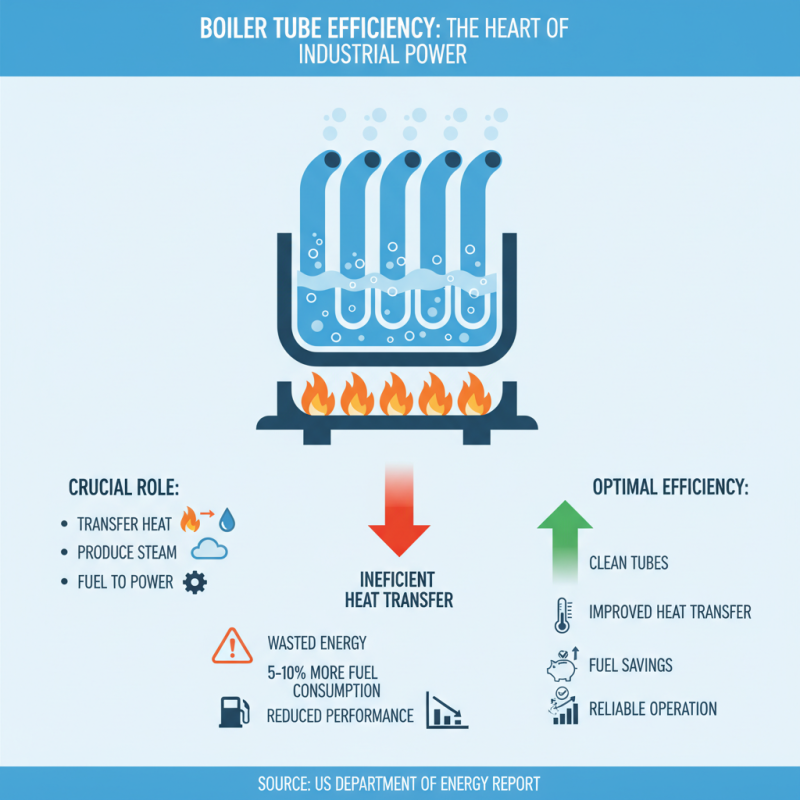

Boiler tubes play a crucial role in the overall efficiency of steam and industrial boilers. They are responsible for transferring heat from burning fuel to produce steam. Inefficient boiler tubes can hinder performance significantly. A report by the Department of Energy states that ineffective heat transfer can lead to a 5-10% increase in fuel consumption. That's a lot of wasted energy.

The design and material of boiler tubes are also essential. For instance, using advanced alloys can enhance heat tolerance and resistance to corrosion. However, even with the best materials, maintenance is key. Periodic inspections are necessary, as many operators neglect this aspect. A lack of routine checks often leads to tube failures, which can be costly. In fact, a study indicates that nearly 40% of boiler failures arise from tube defects.

Understanding how boiler tubes operate enhances maintenance approaches. Monitoring the operational pressure and temperature helps identify issues early. However, it is often the overlooked aspects, such as chemical balance in the water, that cause problems. Regular treatment prevents scaling and corrosion. Ignoring this can result in reduced lifespan and efficiency of tubes. Operators must adopt a proactive mindset. This will help bridge the gap between optimal performance and preventable failures.

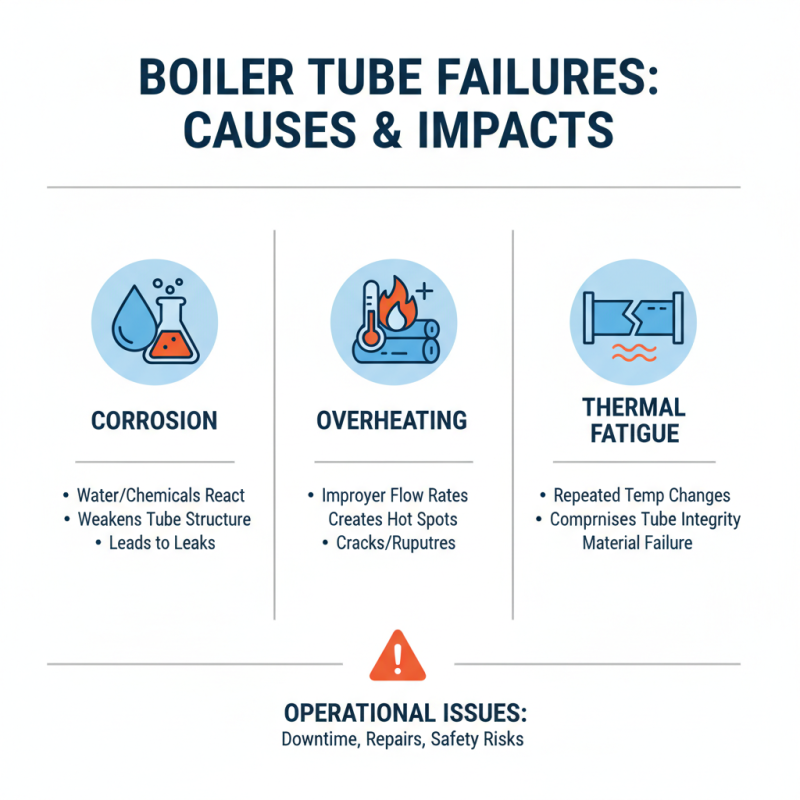

Boiler tube failures can lead to significant operational issues. Common causes include corrosion, overheating, and thermal fatigue. Corrosion occurs when water and chemicals react with the tube material. It weakens the structure and causes leaks. Overheating is often due to improper flow rates. This can create hot spots, leading to cracks or ruptures. Thermal fatigue develops from repeated temperature changes. Over time, this can compromise the tube's integrity.

Here are some tips to improve boiler tube longevity. Regularly inspect tubes for signs of wear and corrosion. Use ultrasonic testing to detect hidden issues. Implement a consistent maintenance schedule. Monitor water chemistry closely to reduce corrosion risk. Adjust flow rates to ensure optimal heat transfer. These practices can help prevent unexpected failures and improve performance.

Understanding the impact of these failures is crucial. A single tube failure can lead to a shutdown. The costs of repairs and lost productivity can be significant. Sometimes, despite best efforts, failures occur. It's essential to learn from these incidents. Analyze root causes and adjust maintenance strategies accordingly for better results.

Maintaining boiler tube efficiency is critical for operational reliability. Regular inspection plays a vital role. According to industry reports, about 30% of boiler failures stem from tube-related issues. These can often be prevented with a proactive approach to maintenance.

Visual inspections should occur at least once a month. Technicians can identify signs of wear or corrosion early. However, many facilities overlook the need for regular checks. Infrared thermography and ultrasonic testing are valuable tools. They can detect hidden issues. Yet, these methods are underutilized in the field.

Cleaning boiler tubes regularly can enhance performance. Scale buildup can reduce heat transfer. Studies show that even a small layer of scale can decrease efficiency by up to 20%. Chemical cleaning and mechanical methods are both effective. But they require skilled personnel to execute. Unfortunately, insufficient training can lead to improper cleaning techniques. This oversight can cause more harm than good, leading to costly repairs later on.

| Inspection Frequency | Maintenance Activity | Common Issues Detected | Preventive Measures |

|---|---|---|---|

| Monthly | Visual Inspection | Corrosion | Regular cleaning and rust inhibitors |

| Quarterly | Ultrasonic Testing | Wall thinning | Material upgrade and monitoring |

| Annually | Hydrostatic Testing | Leakages | Sealing and joint replacement |

| Biannually | Chemical Analysis | Scale buildup | Routine water treatment |

| As Needed | Replacement of Damaged Tubes | Severe damage | Immediate replacement and inspection |

Boiler tube efficiency is crucial for optimal performance. Effective cleaning methods can significantly enhance this efficiency. Regular maintenance is key. A dirty boiler tube reduces heat transfer and increases fuel consumption. This can lead to higher operational costs and frequent breakdowns.

Physical cleaning techniques, like brushing and high-pressure water jetting, are effective. These methods remove scale, soot, and other deposits. However, they require time and skilled personnel. Some facilities neglect this aspect, leading to poor outcomes. Chemical cleaning can also be an option. It effectively dissolves stubborn deposits. Care must be taken, though, as improper use may damage the tubes.

Monitoring the condition of boiler tubes is essential. Visual inspections can identify issues early. Yet, many overlook this step until it's too late. Implementing a regular cleaning schedule can prevent failures. Ignoring boiler maintenance may result in costly repairs. Emphasizing proactive measures can enhance efficiency and prolong the lifespan of the boiler.

Monitoring and analyzing boiler tube conditions is crucial for efficiency. Regular inspections can detect early signs of wear. Using thermography can identify hot spots. These areas may indicate issues that need addressing. Infrared inspections reveal where heat loss occurs. A camera can capture these details effectively.

Data analytics plays a significant role too. Collecting data over time helps predict failures. Statistical analysis can highlight trends in tube performance. Real-time monitoring systems can alert operators to abnormalities. These systems provide alerts before problems escalate. Failing to monitor can lead to unexpected downtime.

Visual inspections should not be overlooked. Techniques like ultrasonic testing help assess wall thickness. This method can detect small cracks before they worsen. Documentation of each inspection is vital. It builds a history that aids in decision-making. Yet, even with thorough monitoring, systems may still fail. It's essential to remain vigilant and ready to adapt.

This chart illustrates the efficiency of boiler tubes over four quarters. Monitoring efficiency is crucial for preventing failures and ensuring optimal performance.