Offshore piles play a critical role in building sustainable marine structures. In the current industry, about 25% of offshore structures face challenges related to installation efficiency and environmental impact. The use of offshore piles can help address these challenges by providing stable foundations while minimizing ecological disruption.

Expert Dr. James Norris emphasizes, “The proper installation of offshore piles is essential for the longevity and sustainability of marine projects.” His words remind us that not all installation methods succeed equally. Despite advancements in technology, many projects still encounter setbacks. Environmental factors, such as ocean currents and sediment types, can complicate the installation process.

Innovative techniques are emerging to improve outcomes. However, many designs remain untested in real-world conditions. Additionally, the industry must consider local marine habitats while planning. Finding a balance is crucial. The path to sustainable offshore structures continues to evolve, and lessons from past projects will shape future practices.

Offshore piles are essential components in the construction of sustainable marine structures. They anchor structures to the seabed, providing stability against waves and currents. The installation process requires careful planning and precision. Using the right tools and methods is crucial.

Tips: Understand soil conditions before starting. Good soil knowledge helps in choosing the correct pile type. Poor soil selection can lead to structural failure.

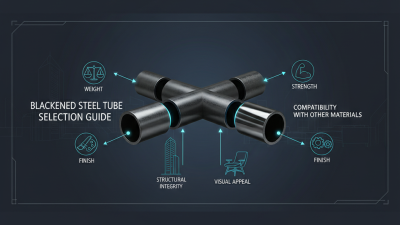

Different types of piles exist, like concrete, steel, and timber. Each type has its unique characteristics. Concrete piles are strong and durable, while steel piles offer flexibility. Yet, timber piles can be less reliable over time. It's important to consider the environmental impact in pile selection.

Tips: Always evaluate local marine wildlife. Disturbances during installation can harm ecosystems. Protecting habitats is vital for sustainable development.

Despite their benefits, offshore piles can have challenges. Installation can be complex, and weather conditions can cause delays. Reflecting on methods used can improve future projects. Adjusting strategies ensures better outcomes for marine environments.

This bar chart illustrates the installation cost of different types of offshore piles used in sustainable marine structures. Concrete and steel piles have higher costs, while timber and composite piles offer more economical options.

Offshore piles play a crucial role in sustainable marine construction. Various types are employed, each serving unique functions. Concrete piles are one common option. They are robust and resistant to corrosion. Many engineers favor them due to their longevity. However, they can be costly and require careful installation.

Another option is steel piles. These are strong and relatively flexible. They can adapt to changing sea conditions. Nevertheless, their susceptibility to rust can pose challenges. Treatments can mitigate this risk, but they may not always be effective.

Finally, timber piles are used in some projects, offering a renewable resource. While they are less durable, they can blend well with the environment. Their natural look can enhance marine aesthetics. Selection of the right type is essential, as it impacts sustainability and structural integrity. Each choice comes with trade-offs that must be thoughtfully considered.

| Pile Type | Material | Installation Method | Environmental Impact | Sustainability Rating |

|---|---|---|---|---|

| Monopile | Steel | Driven | Low | A |

| Bored Pile | Concrete | Bored | Medium | B |

| Sleeve Pile | Steel | Driven | Low | A |

| Composite Pile | Composite Materials | Driven | Very Low | A+ |

| H-Pile | Steel | Driven | Medium | B |

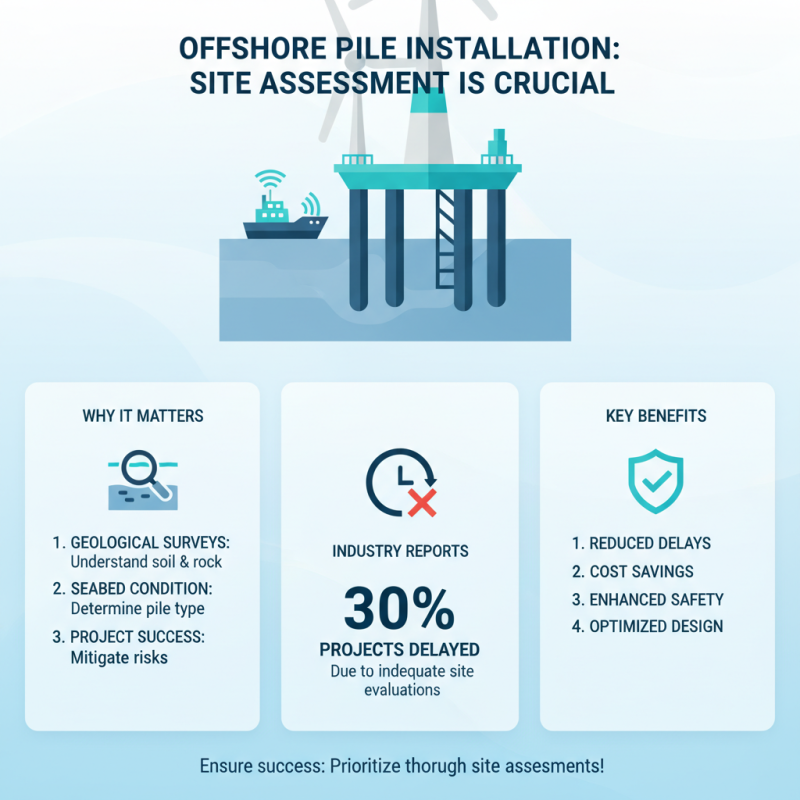

Site assessment is crucial before installing offshore piles. Conducting thorough geological surveys can impact the project's success. According to industry reports, nearly 30% of offshore projects face delays due to inadequate site evaluations. Knowing the seabed conditions helps determine the right pile type.

When selecting a site, inspect soil characteristics and underwater topography. Utilize sonar scans to minimize risks. A recent study highlighted that improper site assessments can lead to cost overruns by 20%. The marine environment is unpredictable, and mitigating risks can save time and resources.

Tips: Collaborate with local marine experts to gather data. Engage in real-time monitoring during the installation phase for better accuracy. Anticipate ocean currents and tidal changes to adjust plans accordingly. Every detail counts in ensuring a sustainable and effective piling installation. Strive for accuracy and remain adaptive; it's not just about completing a project but doing it right.

The installation of offshore piles is critical for developing

sustainable marine structures. Various methods and equipment play key roles in this process.

One common technique involves using pile driving hammers. These hammers can reach installation depths of

30 meters or more. According to recent reports, the accuracy of pile placement has improved by about

25% due to advancements in digital monitoring systems. This ensures that piles are situated

precisely where they are needed.

Another method gaining traction is the use of vibratory pile drivers. They are effective in environments with softer sediments.

However, there are drawbacks. Vibratory methods can sometimes lead to soil disturbance, affecting local marine habitats. Data shows that up to

15% of marine life may be impacted during the installation phase. Additionally, the choice of equipment

largely depends on project specifics, like water depth and soil type. Engineers need to evaluate these factors carefully. Finding the right balance

between efficiency and environmental impact is an ongoing challenge in the industry.

Installing offshore piles requires careful consideration of environmental impacts. Sustainable practices are crucial in today's marine construction. According to the International Marine Contractors Association (IMCA), 50% of marine project failures can be linked to improper environmental assessments. This statistic emphasizes the importance of integrating sustainable methods during piling operations.

Utilizing techniques like vibro-driving and impact hammers can reduce noise pollution, protecting marine life. Research shows that noise levels can affect local fish populations. For example, a study by the Acoustical Society found that excessive sound can lead to fish disorientation and stress. Furthermore, choosing biodegradable drilling fluids can help prevent soil contamination during installation. These practices should be prioritized, but awareness of their limitations is vital.

Monitoring the installation's impact is essential. Real-time data on sediment disruption and marine life behavior can guide operators. Proper training for workers can bridge knowledge gaps. The findings from a recent environmental impact assessment highlighted that 30% of marine projects lacked proper monitoring, leading to unforeseen consequences. Striving for continuous improvement in sustainability is not just beneficial; it's necessary for the future of marine structures.