Helical piles have become increasingly vital in construction over the years. In 2026, their installation techniques will be more advanced. According to Dr. Emily Carter, a leading expert in foundation engineering, "Helical piles offer unique solutions for challenging soil conditions." This demonstrates the growing importance of understanding how to install these systems effectively.

The process requires precision. Workers must ensure that each helical pile is properly positioned. Incorrect installation can lead to structural issues down the line. During the installation, soil conditions play a significant role. Some sites may present unexpected challenges. Awareness of these conditions is crucial for success.

Moreover, continuous education in helical pile installation is essential. New techniques emerge regularly, but many professionals may resist change. The industry must prioritize training to avoid detrimental mistakes. Embracing innovation is necessary for improved safety and efficiency. It's vital to reflect on these aspects as the construction landscape evolves.

Helical piles are increasingly popular in construction. They offer a reliable solution for foundation support in various soil types. Their design allows them to be easily installed in tight spaces. According to industry research, these foundations can reduce settlement risks by nearly 60%. They are ideal for both commercial and residential projects.

The applications of helical piles extend beyond standard foundations. They are also used for communication towers and bridges. A report from the Foundation Performance Association highlights their effectiveness in resisting lateral loads. However, improper installation can lead to uneven settlement. This risk must be evaluated before use. Understanding soil conditions is crucial. Each project presents unique challenges.

While helical piles offer clear benefits, challenges still exist. Installation can be less efficient in rocky soils. The cost may increase if multiple attempts are required. Additionally, local regulations might complicate installation plans. It's vital for engineers to assess these factors early on. Awareness can mitigate potential issues. Balancing speed and care during installation is essential. This approach encourages long-lasting results.

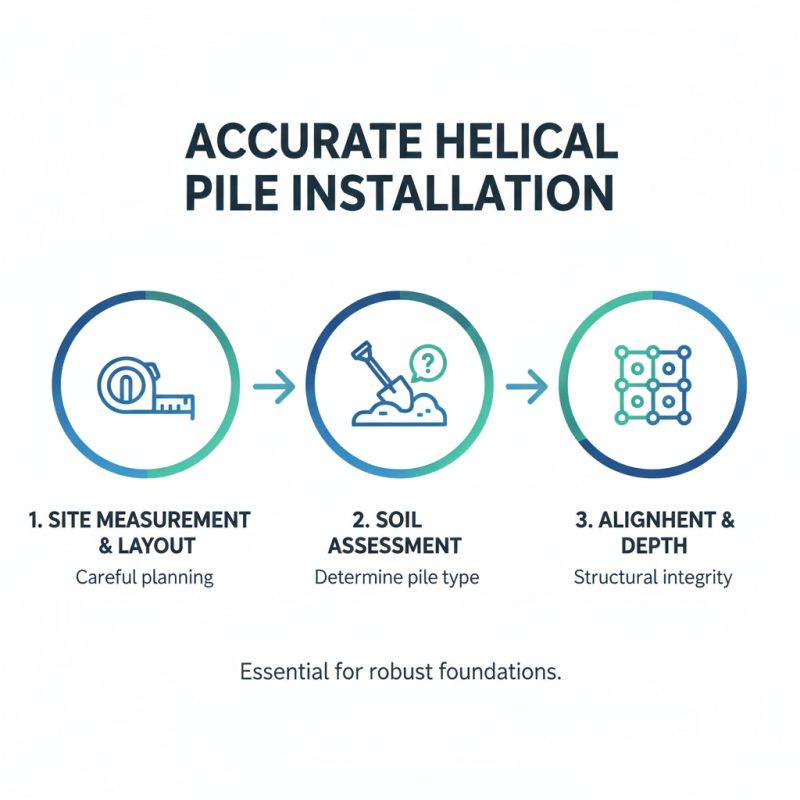

Preparing the site is crucial for effective helical pile installation. Begin by evaluating the soil conditions. Conduct a geotechnical investigation to determine the soil properties. This will help in selecting the right size and type of helical piles. Mark the installation locations clearly on-site. Visibility simplifies the process.

Next, clear the area of any obstacles. Remove rocks, debris, and vegetation. This promotes a safer working environment. Ensuring ample space for equipment is vital. Inspect the site for existing utilities. Neglecting this can lead to dangerous situations. Also, consider the weather conditions. Rain or snow can delay the project. Adverse weather affects soil stability too.

Lastly, ensure proper drainage around the installation area. Water accumulation can undermine the pile's effectiveness. Simple trenches can guide water away. Take time to double-check your preparations. A rushed setup can lead to complications later on. Reflecting on each step is essential for a successful outcome.

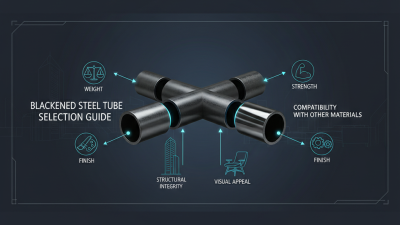

Choosing the right type of helical pile is crucial for successful installations in 2026. Many factors come into play. Soil conditions are a major consideration. For instance, sandy soils often require different pile designs compared to clayey soils. Engineers should analyze soil data from the site. In fact, 65% of project failures in foundation work relate directly to incorrect soil assessments, according to a recent industry report.

Next, consider the load-bearing requirements. Some helical piles can support loads ranging from 10 kips to over 300 kips. Selecting the right pile design can significantly impact long-term stability. It's important to connect with a knowledgeable foundation engineer to understand these requirements. Additionally, anticipate challenges. For example, installation in crowded urban areas may require specific pile lengths. Errors here can lead to increased costs. Ultimately, balancing these factors leads to better project outcomes, but it requires careful thought and planning.

Installing helical piles accurately is crucial for any construction project. The right techniques can significantly impact structural integrity. Measure your site carefully before installation. Knowing soil conditions helps determine the appropriate pile type. Charting out the location of each pile ensures they align with your design specifications.

Tips: Use a level to ensure proper alignment during installation. Check the verticality frequently. This prevents future structural issues. A small mistake can lead to serious problems down the line.

Each installation requires a systematic approach. Begin by preparing the site. Remove any debris or vegetation. Erosion or loose soil can compromise pile stability. After placing the helical piles, monitor their depth during insertion. If resistance increases unexpectedly, pause and assess the situation.

Tips: Always have backup equipment ready. Equipment failures can delay your project. Plan for weather conditions too. Rain or wind may impact safety and accuracy. Reflect on past installation experiences. Identify areas for improvement and apply those lessons to future projects.

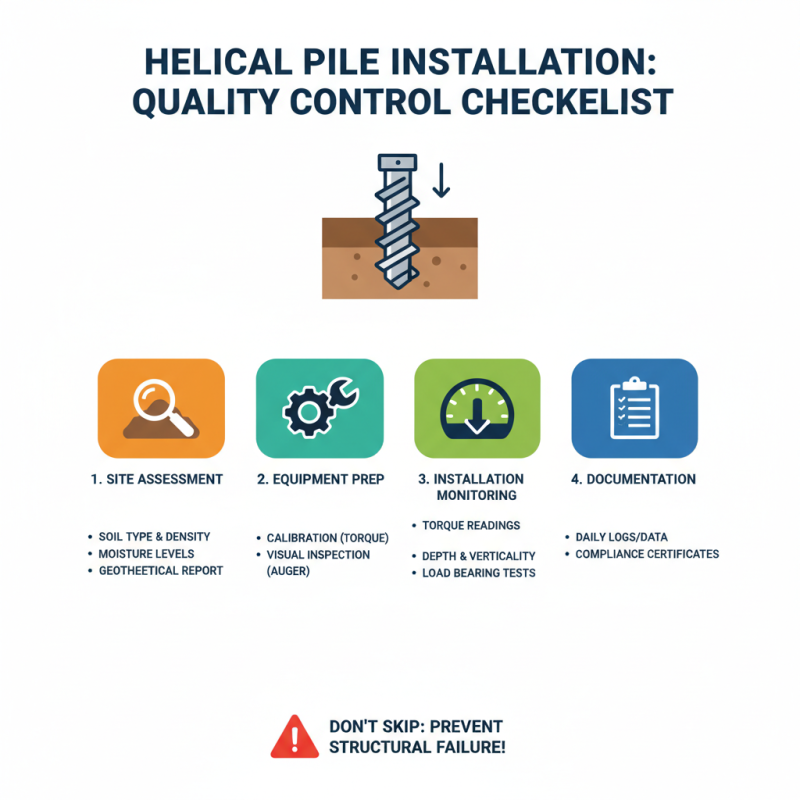

Quality control and testing are crucial in the installation of helical piles. These piles support structures, so ensuring they are properly installed is essential. Start by reviewing the site conditions. Soil type and moisture levels will affect the installation technique. Create a checklist to guide the process. This checklist should include soil assessments and equipment calibration. Skipping these steps might lead to failures later.

During the installation, monitor the torque applied to each pile. This ensures it meets design specifications. It’s vital to understand that not all installations will be perfect. Inconsistent soil conditions can lead to variations in torque readings. Regularly inspect the piles during installation. Look for signs of distress in the equipment or the piles themselves. If there are concerns, pause and reassess.

Testing is equally important after installation. Load testing can confirm the structural integrity of the helical piles. However, some projects may overlook this step, thinking visual inspections are sufficient. This can result in a reliance on assumptions rather than data. Testing offers real insight into the pile’s performance under load. Always aim for comprehensive data collection during both installation and testing phases.