When it comes to construction, material choice matters greatly. One option that stands out is Rectangular Steel Pipe. Its versatility makes it suitable for various applications. Builders appreciate its strength and durability. This type of piping is often used in beams, frames, and supports. The unique shape allows for efficient use of space.

Rectangular Steel Pipe integrates well with other building materials. It offers a strong structural performance that can withstand heavy loads. However, it’s essential to consider specific project requirements. Not all projects may benefit from its use. Sometimes, Round Steel Pipe might be a better fit.

Choosing the right material is a complex decision. Understanding the strengths and weaknesses is vital. While Rectangular Steel Pipe has many advantages, it is not perfect. Reflecting on these factors can lead to better project outcomes. Ultimately, the right choice leads to safer, more durable structures.

When selecting materials for construction, rectangular steel pipe stands out. Its unique shape provides excellent strength-to-weight ratios, making it an ideal choice for various applications. According to a report by the American Institute of Steel Construction, structural steel, including rectangular steel pipe, can withstand heavy loads while remaining lightweight. This feature is crucial for modern architectural designs that prioritize both aesthetics and functionality.

Rectangular steel pipes are also favored for their versatility. They can be easily manufactured to specific sizes, which reduces waste. A study published in the Journal of Construction Engineering highlighted that construction projects utilizing pre-fabricated steel components can save up to 25% in costs. Moreover, these pipes allow for efficient use of space, leading to innovative designs without compromising structural integrity.

While rectangular steel pipes offer many benefits, they are not without challenges. Corrosion can be a concern if they are not properly treated. Projects need to consider long-term maintenance. This often underlines the balance between cost and durability. In the end, careful thought around finishes and coatings can make a significant difference.

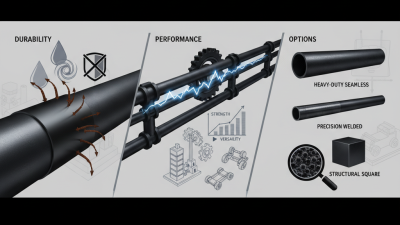

When comparing rectangular and round steel pipes for construction, several factors should be considered. Rectangular steel pipes offer increased structural support for various applications. Their flat sides allow for easy stacking and aligning, making them ideal for building frameworks. By providing greater surface area, they can bear more load than their rounded counterparts.

On the other hand, round steel pipes excel in certain situations as well. Their uniform shape allows for smooth flow of materials. They are often used in plumbing and gas lines. However, they may not provide the same level of stability as rectangular pipes in specific structural applications. It's essential to assess the unique needs of each project.

Not all constructions are alike. Some may require the distinct advantages offered by rectangular pipes. Yet, using round pipes might be more beneficial in others. Finding the right balance between these options can be challenging. Regularly reassessing your choice of materials is crucial for successful construction.

| Dimension | Weight per Meter (kg) | Load Bearing Capacity (kN) | Cost per Meter ($) | Applications |

|---|---|---|---|---|

| Rectangular 50x30 mm | 3.1 | 12.5 | 15.00 | Structural frames, furniture |

| Rectangular 100x50 mm | 6.5 | 25.0 | 25.00 | Building frames, bridges |

| Round 50 mm | 2.5 | 10.0 | 12.00 | Piping, handrails |

| Round 100 mm | 8.0 | 30.0 | 20.00 | Structural support, scaffolding |

Rectangular steel pipes are gaining popularity in construction. Their shape allows for versatile applications. They are often used in structural frameworks, making them ideal for beams and supports. According to industry statistics, about 30% of steel in construction is used in the form of hollow sections, including rectangular pipes. This highlights their importance.

In addition to structural use, rectangular steel pipes serve as essential components in various applications. Many companies utilize them for handrails and fences. They offer strength and durability, ensuring safety and longevity. Industry reports indicate that these pipes can withstand heavy loads, which is crucial for urban construction projects. However, proper welding techniques are essential. Poor welding can compromise structural integrity.

Another significant application is in mechanical frameworks. These pipes are ideal for machinery and equipment supports. They can be easily cut and fabricated to meet specific requirements. However, one must be cautious about corrosion resistance. Not all rectangular steel pipes are treated to prevent rust, which can lead to costly repairs. It's essential to evaluate the environment where they will be installed.

When considering materials for construction, the strength and durability of rectangular steel pipes stand out. These pipes are known for their impressive load-bearing capabilities. According to a report by the American Institute of Steel Construction, rectangular steel sections can withstand high levels of stress and strain. This makes them ideal for heavy-duty applications. The yield strength of high-quality rectangular steel is often over 36,000 psi, which is remarkable for structural integrity.

Rectangular steel pipes also excel in resisting environmental damage. Tested under various conditions, they demonstrated minimal corrosion when properly coated. A study from the National Institute of Standards and Technology indicated that galvanized rectangular pipes can last over 50 years in moist environments without significant degradation. This durability saves money in the long run, reducing maintenance costs and replacement frequency.

Tip: Always assess the load requirements before selecting pipe sizes. This can prevent over-sizing or under-sizing for your project needs.

Using rectangular steel pipes can also introduce complexity. Fabrication and installation may require precision. Hence, it is essential to work with skilled technicians to ensure quality. Consider investing in training for your team to handle these materials effectively.

Tip: Regular inspections can help identify wear early, ensuring the longevity of your investment.

The choice of rectangular steel pipes in construction often highlights cost-effectiveness. They offer a strong yet lightweight option for various structures. This translates to lower transportation and handling costs. Contractors appreciate how easy these pipes are to work with on-site. They can be cut and welded quickly, saving time during installation.

Sustainability is another significant factor when selecting rectangular steel pipes. Steel is recyclable, reducing waste in landfills. This makes it a preferred choice for environmentally conscious projects. However, it’s crucial to consider the sourcing of the steel. Materials should come from reputable suppliers to ensure sustainability claims are valid. Not all suppliers prioritize eco-friendly practices, leading to potential dilemmas.

Furthermore, while steel pipes are durable, they can corrode over time if not treated properly. This raises questions about maintenance and longevity in certain environments. The overall life cycle of these pipes depends on proper care. Inadequate maintenance can lead to increased costs down the line, challenging their initial cost-effectiveness. It’s essential to weigh these factors when making decisions.