Choosing the right Nickel Alloy Plate can be a daunting task. Experts agree on its importance. John Smith, a leading authority in material science, once stated, "The right Nickel Alloy Plate can make all the difference in a project." This emphasizes the need for careful consideration.

Nickel Alloy Plates are essential in various industries. They offer strength and corrosion resistance. Selecting the right one means understanding your project requirements. Factors such as temperature, environment, and mechanical stress all play a role. Sometimes, people overlook these details, leading to costly mistakes.

It's not just about picking a plate. Each project presents unique challenges. An ideal Nickel Alloy Plate must align with specific needs. Failing to address these can result in inefficiency or failure. Thus, take time to evaluate your options thoroughly. A well-informed choice leads to success.

Nickel alloys are essential materials in various industries. They are known for their excellent corrosion resistance and high-temperature strength. Understanding these properties helps in choosing the right alloy for your project. The composition varies, affecting performance in different environments.

When selecting a nickel alloy, consider your specific application. Some alloys work well in marine settings, while others excel in chemical processing. Each alloy has unique properties. Researching these can save time and resources.

**Tips:**

- Look for guidance on corrosion resistance levels.

- Evaluate mechanical properties needed for your project.

- Be aware that the cost may reflect quality.

Every project is unique. Sometimes, trial and error leads to the best results. Gather samples before making a decision. This approach minimizes risks. Test in real-life scenarios to see how the alloy performs.

When choosing a nickel alloy plate, understanding project requirements is essential. Start by considering the environment where the alloy will be used. High temperatures or corrosive substances can dictate the type of alloy needed. Does your project involve marine applications? If so, a nickel alloy with superior corrosion resistance is crucial.

Next, focus on mechanical properties. Strength, ductility, and fatigue resistance should align with what your project demands. Sometimes, specifications may overlap. This can lead to confusion about which material is best. Don't overlook the importance of weldability. Difficulties in welding can complicate production.

Finally, keep your budget in mind. Nickel alloys can be expensive. You may find a cheaper alternative that meets most requirements. However, cutting costs can sometimes backfire, leading to premature failures. Reflect on the long-term implications of your material choice. Prioritizing short-term savings could result in higher costs later.

When selecting a nickel alloy plate, it’s crucial to compare the various types available. Nickel alloys come in many forms, each designed for specific applications. Some of the most common include Inconel, Monel, and Hastelloy. Each of these alloys has unique properties that can influence your project's outcome.

Inconel is known for its excellent high-temperature strength. It resists oxidation and corrosion. This makes it ideal for aerospace and chemical industries. Then there's Monel, which offers great resistance to seawater corrosion. It’s suitable for marine applications, but not always the cheapest option.

Hastelloy, with its remarkable resistance to harsh environments, can handle extreme conditions. However, it might be overkill for simpler projects.

You must weigh these characteristics against your project needs. Are you working in a moderate climate or under intense heat? Your choice shouldn't merely hinge on price. Reflecting on the purpose of the plate is essential. Sometimes, the cheaper option may lead to greater costs down the line. Always consider the long-term implications of your choice. Each alloy you choose carries trade-offs. Make sure to analyze and understand these before making a decision.

When selecting a nickel alloy plate, it’s crucial to evaluate its performance characteristics. Nickel alloys are renowned for their corrosion resistance and high-temperature stability. According to recent data, around 60% of industries use nickel alloys in extreme environments. This includes chemical processing and aerospace applications. A detailed assessment can ensure the right material is chosen.

The properties of nickel alloys can vary significantly. For instance, some alloys have excellent resistance to pitting and stress corrosion cracking. This makes them ideal for marine applications. Others excel in thermal stability, making them suitable for high-temperature settings. Data suggests that alloy compositions need careful consideration; even a slight change can alter performance.

Cost-effectiveness is another factor. While nickel alloys can be pricey, their longevity can offer long-term savings. However, not every project requires the same grade or type of alloy. Sometimes, lesser-known options might yield better results for specific applications. A thorough understanding of project requirements will guide better decisions.

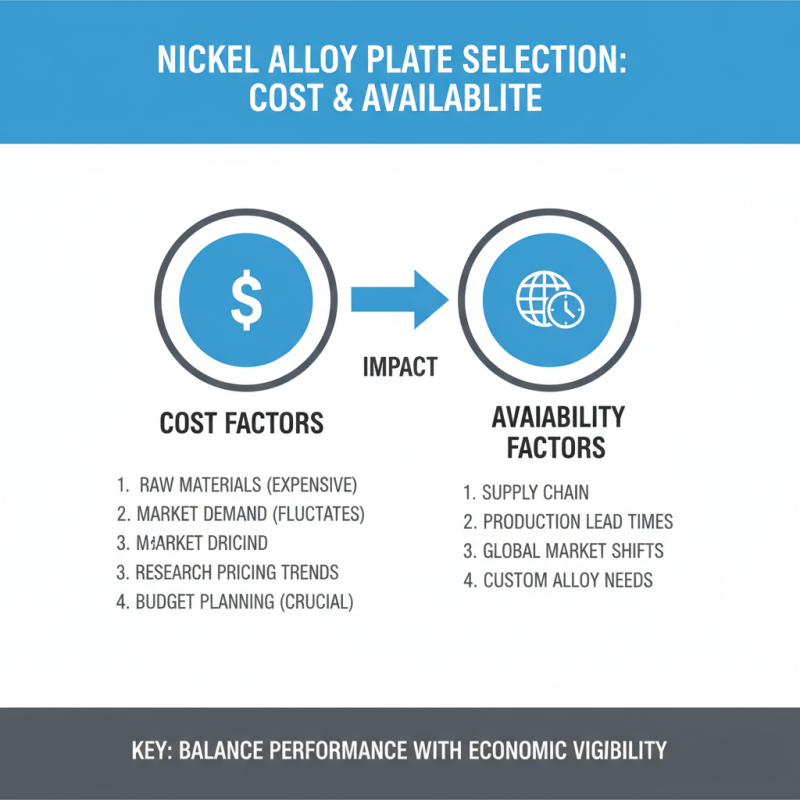

When selecting a nickel alloy plate, cost and availability are crucial factors. Nickel alloys can be expensive due to the raw materials involved. Prices often fluctuate based on market demand. This makes it essential to conduct thorough research on current pricing trends. Understanding your budget is vital. A lack of clear budget planning can lead to overspending.

Availability can also pose challenges. Some nickel alloys may have limited supply. This requires careful consideration of your project timeline. Delays in material acquisition can impact project delivery. Look for local suppliers or distributors to enhance accessibility. However, even local options may not carry all required grades. This adds complexity to the decision-making process.

Moreover, understanding the quality vs. cost dilemma is important. Cheaper materials may compromise performance. Ensure that the selected alloy meets your project's specifications. If unsure, consult with a metallurgist or a material specialist. Their guidance can be invaluable. Navigating the world of nickel alloys can be tricky, but informed choices lead to better outcomes.