When embarking on projects that require durable and reliable materials, selecting the right components is critical to success. Galvanized Round Tubing, known for its corrosion resistance and strength, has become a popular choice among engineers and builders alike. Industry expert John Smith, a structural engineer with over 15 years of experience, emphasizes the importance of making informed decisions in material selection, stating, "The longevity and reliability of a project hinge significantly on the quality of materials used, and Galvanized Round Tubing consistently delivers on those fronts."

As various applications demand specific characteristics from materials, understanding the nuances of Galvanized Round Tubing can streamline your project and enhance overall performance. From construction to manufacturing, the tubing provides versatility and robustness, making it a preferred option for diverse settings. However, choosing the right type, size, and specifications is essential to fully leverage its benefits.

In this guide, we will explore essential tips for selecting Galvanized Round Tubing that will not only meet your project requirements but also ensure durability and cost-effectiveness. With insights from industry leaders and practical advice, you can navigate the selection process confidently and set your projects up for success.

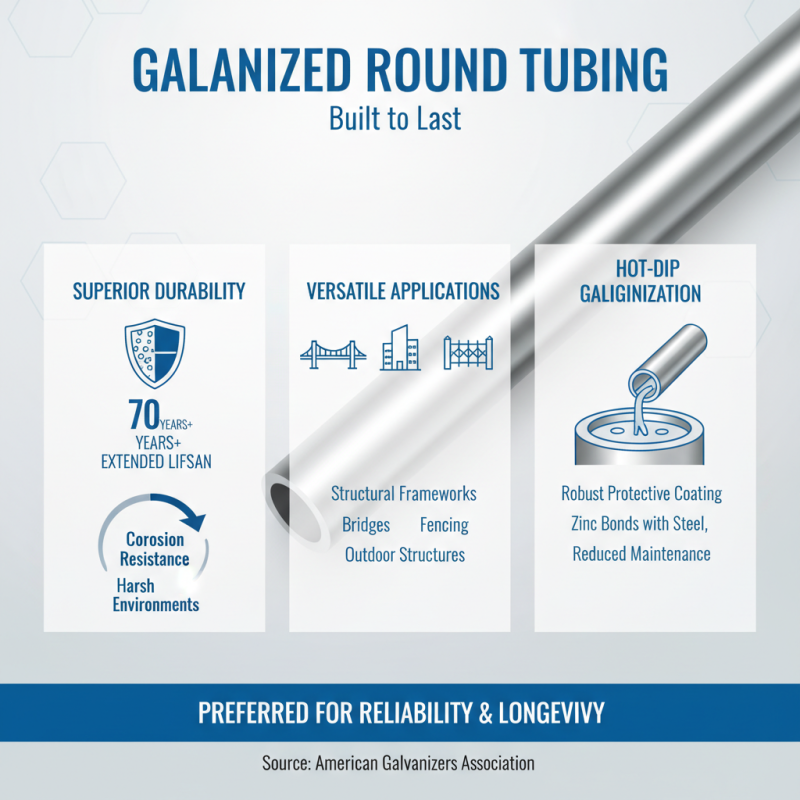

Galvanized round tubing is a popular choice for various construction and engineering projects due to its robust composition and numerous benefits. This type of tubing is made from steel that has been coated with a layer of zinc through a process known as galvanization. This coating serves as a protective barrier, preventing corrosion and enhancing the tubing's durability. The combination of steel's strength and zinc's anti-corrosive properties results in a material that can withstand harsh environmental conditions, making it ideal for both indoor and outdoor applications.

The benefits of using galvanized round tubing extend beyond mere corrosion resistance. Its lightweight nature, coupled with impressive tensile strength, allows for easy handling and installation without sacrificing structural integrity. Galvanized tubing can also be easily welded, cut, and shaped, which adds to its versatility in various projects, including fencing, scaffolding, and support structures. Furthermore, the smooth surface finish of the tubing not only provides aesthetic appeal but also prevents the buildup of dirt and debris, contributing to its low maintenance requirements.

When selecting galvanized round tubing for your projects, several key factors must be taken into account to ensure that you choose the right materials for your needs. First and foremost is the wall thickness of the tubing. A thicker wall provides added strength and durability, making it suitable for heavy-duty applications, while a thinner wall might be more appropriate for lighter, more aesthetic projects. Always consider the load requirements of your specific usage to determine the necessary wall thickness.

Another important factor to consider is the diameter of the tubing. The size you select can significantly impact the overall functionality of your project. Larger diameters typically allow for better fluid flow or structural support, while smaller diameters can be used for decorative or lighter applications. Ensure that you carefully measure the intended space or requirement to find the right fit.

Tips for choosing galvanized round tubing include consulting with suppliers about the specific environmental conditions the tubing will face. If your project is exposed to harsh weather conditions, selecting a product with appropriate galvanization can ensure longevity and resistance to corrosion. Additionally, always seek out options that align with your project’s budget without compromising on the quality needed for safety and effectiveness.

When selecting galvanized round tubing for your projects, understanding the industry standards, particularly those set by ASTM (Americans Society for Testing and Materials), is crucial. ASTM A53 and ASTM A500 are common specifications that ensure the tubing meets specific mechanical properties and chemical compositions. For instance, ASTM A53 outlines two grades, Grade A and Grade B, with Grade B offering higher tensile strength, making it suitable for structural applications. Adhering to these standards guarantees that the tubing withstands the rigors of various environmental conditions, ensuring longevity and reliability in applications like construction and manufacturing.

Moreover, beyond ASTM standards, it is essential to consider additional certifications or compliance with local codes, which might dictate certain specifications for galvanized tubing. According to a report by the International Organization for Standardization (ISO), adherence to these standards can significantly reduce the risk of project delays and enhance the overall safety of the construction.

Tip 1: When purchasing galvanized round tubing, always verify if the supplier provides documentation that confirms adherence to ASTM standards. This diligence ensures that you receive a product that is not only durable but also compliant with safety regulations.

Tip 2: Consider the end-use of the tubing when choosing between different grades. For instance, if your project involves high-stress applications, opting for higher-grade options like ASTM A500 Grade C can offer better performance and reliability.

Tip 3: Regularly stay updated with industry standards and changes by engaging with relevant industry bodies and publications. This proactive approach will help you make informed decisions and maintain compliance with the latest safety and quality requirements.

| Dimension (inches) | Weight (lbs/ft) | Wall Thickness (inches) | Application | Industry Standard |

|---|---|---|---|---|

| 1.00 | 1.68 | 0.065 | General Construction | ASTM A53 |

| 1.25 | 2.18 | 0.065 | Fencing | ASTM A500 |

| 1.50 | 2.76 | 0.065 | Agricultural Equipment | ASTM A53 |

| 2.00 | 4.00 | 0.065 | Scaffolding | ASTM A500 |

| 2.50 | 5.79 | 0.065 | Structural Components | ASTM A36 |

Galvanized round tubing is a versatile material widely used in various construction projects, thanks to its excellent corrosion resistance and durability. According to the American Galvanizers Association, hot-dip galvanization provides a robust protective coating that can extend a steel structure's lifespan by up to 70 years, making it a preferred choice for projects exposed to harsh environmental conditions. This durability is particularly advantageous in applications such as structural frameworks, where strength and longevity are critical.

One of the most common applications of galvanized round tubing is in the construction of scaffolding and support structures. Its lightweight properties combined with high tensile strength make it suitable for temporary and permanent scaffolding systems, providing safe working conditions for construction teams. Additionally, galvanized round tubing is often employed in fencing and railing applications where both aesthetic appeal and structural integrity are paramount. According to industry reports, the fencing market is projected to grow significantly, further emphasizing the need for reliable materials like galvanized tubing that can withstand the test of time while maintaining a minimal maintenance requirement. This makes galvanized round tubing not only a practical choice but also a financially sound investment in the construction sector.

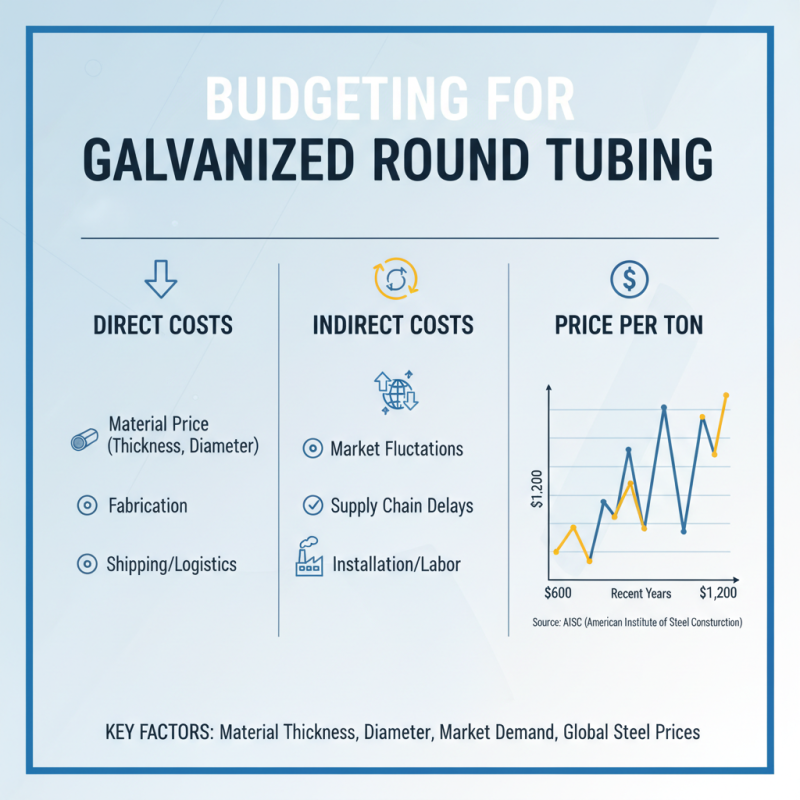

When budgeting for galvanized round tubing in your projects, it’s essential to consider both the direct and indirect costs involved. The average price for galvanized round tubing can vary significantly based on factors such as material thickness, diameter, and market demand. According to the American Institute of Steel Construction, the price per ton for galvanized steel has fluctuated between $600 and $1,200 in recent years, driven largely by global steel prices and supply chain dynamics. Understanding these fluctuations is crucial for accurate budgeting.

Additionally, beyond the upfront costs of purchasing galvanized round tubing, project managers must account for potential long-term expenses associated with maintenance and installation. Studies show that galvanized steel reflects a longer lifespan compared to non-galvanized products, often outlasting its competitors by more than 50%. This longevity can result in lower lifecycle costs, making galvanized round tubing an economical choice over time. Accurate budgeting should therefore factor in not just the initial expenditure but also the anticipated savings through reduced maintenance and replacement costs, which can significantly affect the overall project budget.