When it comes to construction projects, the material you choose is crucial. One option that stands out is Black Welded Pipe. This pipe is often favored for its strength and resilience. Its unique properties make it suitable for various applications.

Construction professionals appreciate the durability of Black Welded Pipe. It can withstand high pressure and harsh conditions. Some might overlook its advantages, focusing on other materials instead. However, this could be a mistake. The cost-effectiveness of Black Welded Pipe can't be ignored, either. It offers long-term savings that contribute to project efficiency.

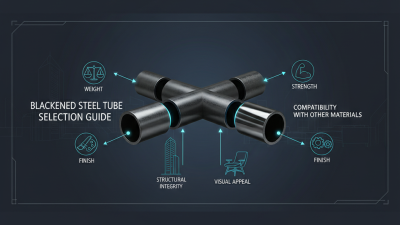

In addition to its practical benefits, Black Welded Pipe has aesthetic appeal. Its dark finish can enhance the overall design of construction projects. Yet, not all situations call for it. It's essential to evaluate your specific needs. Ultimately, Black Welded Pipe could be the ideal choice for your next project.

Black welded pipe is a popular choice in many construction projects. Its strength and durability make it suitable for a variety of applications. This pipe type offers a robust solution for structural support, making it attractive for builders and engineers alike.

One significant benefit of black welded pipe is its resistance to corrosion. This property is vital, especially in environments exposed to moisture. The finish of black pipe helps it withstand rust better than other types. Its adaptability is another advantage. It can be used for plumbing, heating systems, and even industrial applications. However, proper treatment and maintenance are crucial. Without care, the benefits may diminish over time.

Another consideration is the ease of installation. Black welded pipe is lightweight and easier to handle than heavier alternatives, which can speed up project timelines. Yet, it requires skilled labor for welding. Poor quality welds can lead to failures and leaks. Proper training for workers is essential to maximize the pipe's advantages. In any case, thoughtful selection can lead to successful construction outcomes.

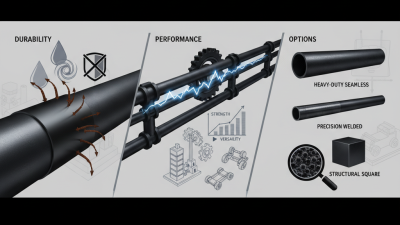

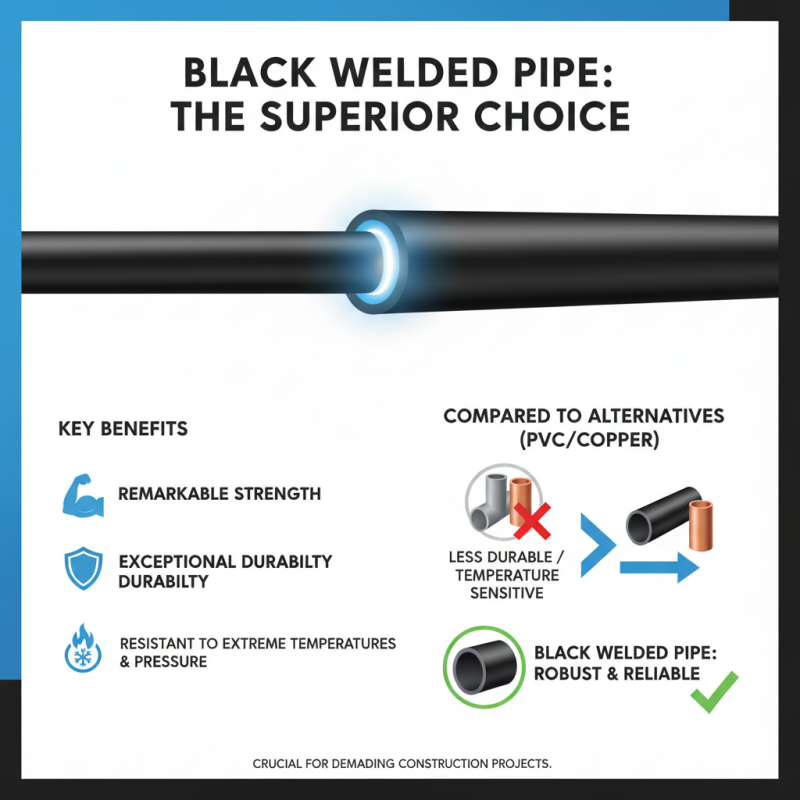

When it comes to construction, choosing the right materials is crucial. Black welded pipe offers remarkable durability and strength, making it a popular choice. Compared to alternatives like PVC or copper, black welded pipe stands out. It’s resistant to high pressure and extreme temperatures, which is vital for many projects.

One key advantage is its resistance to corrosion. This allows the pipe to handle harsh environmental conditions effectively. Black welded pipe can last for decades with proper care. It retains structural integrity, even under substantial stress. However, installation must be done correctly to ensure safety.

**Tip:** Always inspect the pipes before installation. Look for any damages or signs of wear.

While black welded pipe is strong, it’s important to be aware of potential challenges. It can be heavier than other options, requiring more labor for handling. Furthermore, it needs regular maintenance to prevent rusting if not properly coated.

**Tip:** Consider using protective coatings to enhance lifespan. Proper sealing can significantly reduce rust risks.

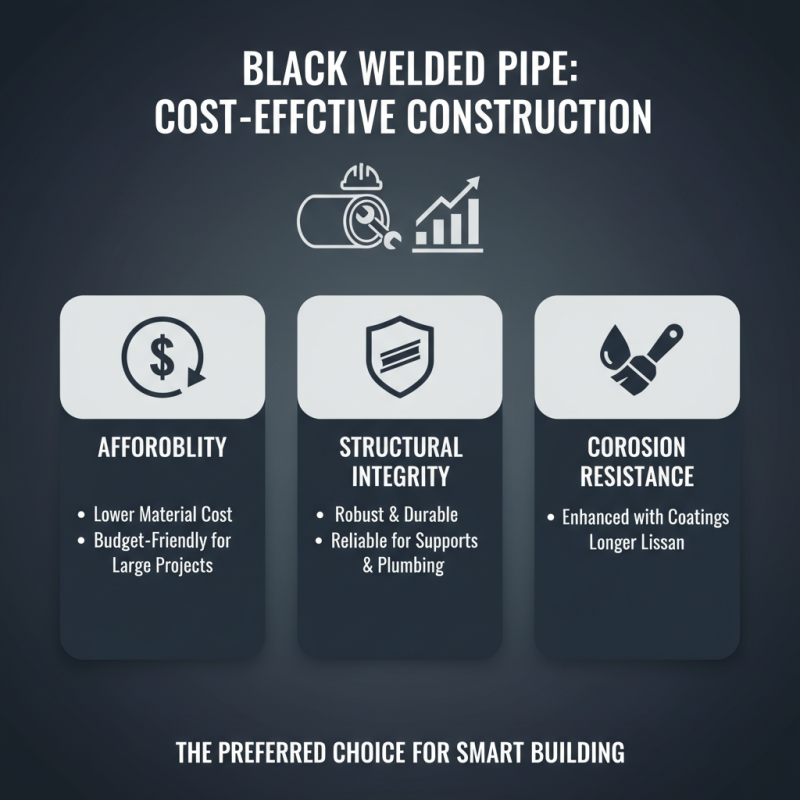

When it comes to large-scale construction projects, cost-effectiveness is crucial. Black welded pipe is often a preferred choice. It offers structural integrity at a lower price compared to other materials. This affordability makes it suitable for various applications, from plumbing to structural supports. The black finish also allows for better corrosion resistance when protective coatings are applied.

The production process of black welded pipe can be less expensive, making it a cost-efficient option. However, the quality can vary by manufacturer. It’s important to assess the reliability of your supplier. Cheap pipes might save money upfront but lead to higher maintenance costs later. This can affect your project timeline too.

**Tips:** Always check for certifications when purchasing. Look for pipes that meet industry standards. Inspect the weld quality before use. A small investment in quality can save future headaches. Remember, not all black pipes are created equal; research and due diligence are essential.

When considering materials for construction projects, black welded pipe stands out. Its resistance to corrosion is a key benefit. This type of pipe is coated with a layer of oil to prevent rust. Yet, it requires regular maintenance to ensure longevity. Without proper care, corrosion can still occur. Regular inspections can help catch issues early.

The choice of black welded pipe also involves weighing its durability against maintenance needs. It’s sturdy and solid, but improper storage can lead to damage. Water and moisture can degrade the coating. Proper storage and the right conditions are crucial for maintaining its integrity. Additionally, its surface can be vulnerable if scratches occur. When that happens, corrosion risks significantly increase.

Understanding the balance between corrosion resistance and maintenance is vital. Many overlook necessary upkeep, thinking the material will last indefinitely. It’s easy to ignore small signs of wear, but this can be costly later. Regular inspections and prompt repairs are the best practices to follow. Ultimately, investing time in maintenance can enhance the lifespan of black welded pipes and ensure the success of your construction projects.

| Feature | Description | Benefits | Maintenance Considerations |

|---|---|---|---|

| Corrosion Resistance | Black welded pipes are coated to resist rust and corrosion. | Increased lifespan and reduced need for replacement. | Regular inspection is recommended to ensure integrity. |

| Cost-Effectiveness | Generally lower initial costs compared to stainless steel alternatives. | Budget-friendly for large-scale projects. | Needs protective coatings to maintain low cost over time. |

| Versatility | Suitable for various applications including plumbing and structural support. | Wide range of uses for diverse construction needs. | Ensure compatibility with surrounding materials to avoid chemical reactions. |

| Ease of Installation | Lightweight and easy to handle which simplifies the installation process. | Reduced labor costs and time savings during construction. | Training may be needed for optimal installation techniques. |

Black welded pipe is widely used in construction due to its durability and strength. It is commonly employed in plumbing, gas lines, and structural applications. The advantages it offers make it a preferred choice. However, not all applications benefit from its properties.

In the industrial sector, black welded pipe plays a key role in transporting fluids and gases. It has excellent resistance to high pressure. Many factories rely on this material for their pipeline systems. Yet, it can be prone to corrosion if not properly maintained, leading to potential issues. Regular inspections are crucial for ensuring safety and reliability.

In residential construction, black welded pipe is often used for furniture and fixtures. Its industrial look has gained popularity in interior design. Many homeowners appreciate its aesthetic appeal. However, there are challenges in using it, such as requiring proper welding techniques to avoid leaks. Ensuring skillful installation is essential to prevent future problems.