When embarking on a new construction or manufacturing project, the choice of materials is crucial. Metal Tube Pipe is often a go-to option for many engineers and builders. Its versatility and strength make it ideal for various applications, from structural support to fluid transport.

Different types of Metal Tube Pipe exist, each with unique properties. Knowing these distinctions can significantly affect your project's success. For instance, some metal pipes resist corrosion better, while others are tailored for high-pressure environments. This overview will explore ten of the best types available, highlighting their unique features and uses.

Selecting the right Metal Tube Pipe requires careful thought. It's essential to consider factors like the environment and specific project requirements. You might encounter challenges, such as balancing cost with quality. However, making informed decisions is possible by understanding these key materials.

When considering metal tube pipes for various projects, the choice of materials is crucial. Steel, for instance, stands out for its strength and durability. According to the American Iron and Steel Institute, up to 48% of structural steel used in construction is made from recycled materials. This makes steel an environmentally friendly option. However, rust and corrosion can be issues. Proper treatment and coatings are essential to ensure longevity.

Aluminum tubing is lightweight yet strong. It offers an impressive strength-to-weight ratio that is attractive for many applications. According to a report by the Aluminum Association, aluminum's market is forecasted to grow by 10% annually. Despite its advantages, aluminum can be more costly than steel. Careful budget planning is vital to address this discrepancy.

Copper pipes are another option. Widely used in plumbing, they resist corrosion exceptionally well. The Copper Development Association notes that copper’s antibacterial properties make it ideal for piping in healthcare settings. Nevertheless, sourcing copper can be challenging due to fluctuating prices. Often, this leads to project delays as costs are reassessed. Each material has its pros and cons, which should be navigated with careful consideration.

When selecting a metal tube for structural applications, strength is paramount. Different types of metal tubes offer varying levels of durability and weight. For heavy-duty projects, steel tubes are usually favored. They provide excellent tensile strength, crucial for load-bearing structures. However, they can be prone to corrosion if not properly treated.

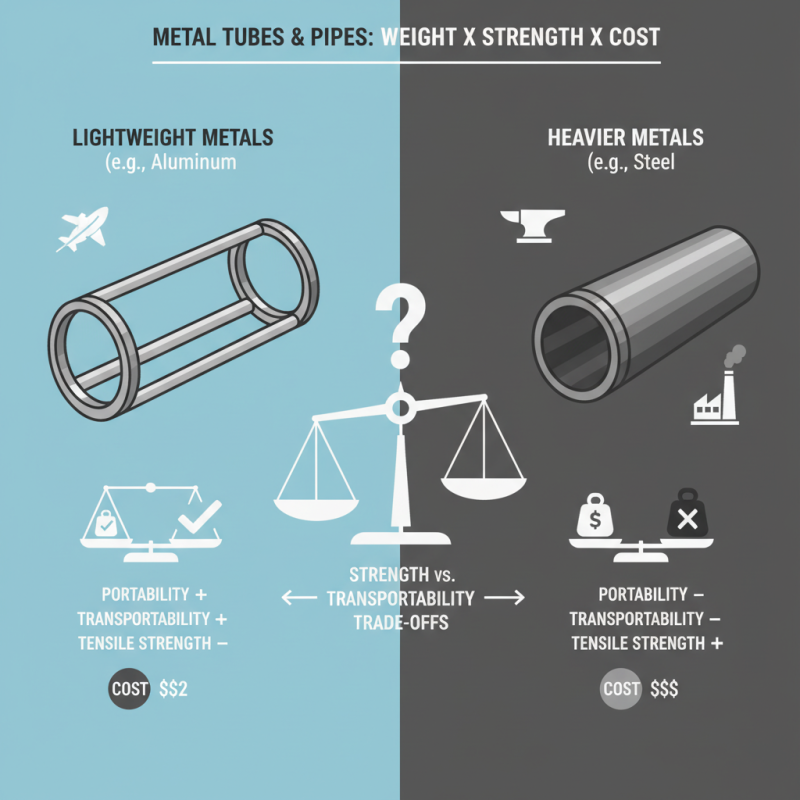

Aluminum tubes, on the other hand, are lightweight and resistant to corrosion. This makes them ideal for applications where weight reduction is critical. Yet, they often lack the strength of steel. This presents a dilemma for engineers.

Choosing between strength and weight can be a tricky balance.

Also, consider the shape of the tube. Round, square, or rectangular tubes each have unique strengths. Round tubes handle pressure well, while square and rectangular tubes resist bending effectively. In choosing the right type, understanding the project's specific needs is crucial. Reflecting on these details can lead to better material choices. Striking that balance can often require re-evaluation as projects evolve.

When selecting metal pipes for durability, corrosion resistance is key. Different metals react uniquely to environmental factors. Steel, for instance, offers strength but can rust if not galvanized. It’s a classic choice but requires maintenance. Regular inspections become a must, as small issues can escalate quickly.

Stainless steel, on the other hand, resists corrosion much better than regular steel. Its chromium content forms a protective layer, making it suitable for outdoor projects, reducing worry about rust. However, it can be pricier, leading some to reconsider budgets.

Aluminum pipes are lightweight and resist corrosion as well. They are easy to work with but may not bear heavy loads over time.

Copper pipes have long been a favorite for plumbing due to their anti-microbial properties. Corrosion can still occur if water quality is poor. Regular checks on water conditions can prevent headaches later. Each type of metal has advantages and drawbacks. Understanding the environmental conditions helps in making an informed choice.

When budgeting for metal tube materials, it’s vital to consider the cost differences among various types. Steel usually offers the most cost-effective solution, with average prices around $0.50 to $1.50 per pound. However, galvanized steel can fluctuate significantly, costing between $0.70 and $2.00 per pound. Despite its affordability, it can corrode over time, adding maintenance costs.

Aluminum provides an alternative with a price range of $2.50 to $4.00 per pound. It is lightweight and resistant to rust, but the initial investment is higher. According to the Metal Fabrication Industry Association, aluminum consumption in construction has increased by 6.5% annually, reflecting its growing popularity. Yet, some projects may overlook this option due to initial costs, missing out on long-term savings.

Copper, while aesthetically pleasing, is often cited as a poor budget choice, averaging $3.00 to $4.50 per pound. Its high price may restrict usage in larger applications. Current economic factors also affect its availability and price, making it less accessible. Evaluating these material costs reveals the need for careful planning. Balancing upfront expenses with potential long-term value is crucial for every project.

When designing with metal tubes and pipes, weight often plays a crucial role. The balance between strength and transportability can affect both functionality and cost. Lightweight metals like aluminum may be ideal for portable structures. However, they might lack the tensile strength found in heavier materials such as steel. Choosing the right material involves trade-offs.

Consider the project’s requirements. If you need high structural integrity, heavier metals may be necessary. Yet, transporting these materials could be cumbersome. The choice can impact not just the build but also the budget. For instance, heavier pipes might lead to higher shipping costs. Conversely, lighter options may need reinforcement in other areas.

Keep in mind that every project is unique. It’s vital to reflect on how these choices influence overall design. The ideal metal tube or pipe type requires a careful analysis of needs versus practicality. Achieving a balance is essential to meet project goals effectively. Careful consideration today leads to better outcomes tomorrow.