In the realm of industrial materials, the choice of tubing is pivotal for ensuring both durability and performance. Among the various options available, the "Blackened Steel Tube" has emerged as a favorite due to its unique properties that combine strength with resistance to environmental factors. Expert metallurgist Dr. Emily Thompson emphasizes this point by stating, "The application of a blackened finish not only enhances the aesthetic appeal of steel tubing but also provides a protective layer that extends its lifespan." This statement underscores the significance of selecting high-quality tube options for optimal performance in demanding conditions.

Blackened Steel Tubes are particularly renowned for their versatility across various applications, ranging from construction to manufacturing. Their enhanced protection against rust and corrosion makes them ideal for environments where exposure to moisture is an ongoing concern. As industries continue to evolve and seek materials that offer both durability and functionality, the demand for robust solutions like the Blackened Steel Tube remains ever-relevant.

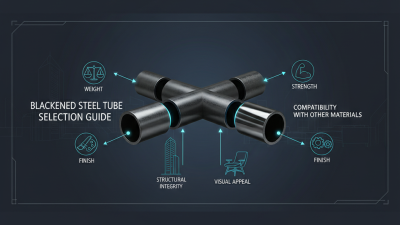

As we delve into the best options available, understanding the properties and benefits of Blackened Steel Tubes will empower manufacturers and engineers to make informed decisions for their projects. In the following sections, we will explore the leading choices in the market, assessing their performance metrics and durability to guide you in selecting the best fit for your needs.

When it comes to selecting blackened steel tubes for construction or manufacturing, enhanced corrosion resistance is crucial to ensure longevity and reliability. Blackened steel typically undergoes a process that involves applying a protective layer, which not only improves its aesthetic appeal but also serves as a barrier against environmental factors. The method of blackening can vary, but the primary goal remains to minimize the impact of moisture and chemical exposure that can lead to corrosion over time.

One effective option for improving corrosion resistance is the use of tubes treated with advanced coatings or finishes. These coatings can provide additional protection beyond the traditional blackening process, often incorporating rust inhibitors and moisture-resistant properties. Additionally, selecting a steel grade that has inherent corrosion-resistant qualities can further enhance the durability of the tubes. Considerations such as the thickness of the material and the environmental conditions in which the tubing will be used are also critical, as they can influence the overall effectiveness of the corrosion resistance measures in place.

By focusing on enhanced corrosion resistance, users can ensure that their applications—whether in structural supports, automotive components, or piping systems—will withstand the rigors of their intended environments. The combination of well-treated blackened steel tubes and appropriate maintenance can lead to significant improvements in service life, making them a smart choice for a variety of applications.

When it comes to choosing between blackened and galvanized steel tubes, durability and performance are critical factors to consider. Blackened steel tubes are coated with a black oxide finish, which provides a degree of rust resistance while maintaining a sleek appearance. According to industry reports, blackened steel is commonly used in applications that prioritize aesthetics alongside functional durability, such as architectural and decorative elements. The black oxide layer offers some corrosion protection, but it ultimately requires regular maintenance to ensure longevity—particularly in environments prone to moisture.

In contrast, galvanized steel tubes are coated with a layer of zinc, offering superior corrosion resistance. Studies indicate that galvanized steel can have a lifespan of up to 50 years in outdoor applications, compared to approximately 5-10 years for blackened steel if not adequately maintained. The galvanization process forms a protective barrier that withstands harsh weather conditions, making it an excellent choice for structural applications and environments exposing the tubes to various corrosive elements. Consequently, while blackened steel may be favored for specific aesthetic applications, galvanized steel often proves to be the more durable option for industrial and structural uses, providing long-term performance and reliability.

When evaluating blackened steel tubes for structural applications, several key performance metrics are essential to ensure durability and reliability. One of the most critical metrics is tensile strength, which typically ranges from 350 to 550 MPa for blackened steel. According to a report by the American Institute of Steel Construction, this level of tensile strength makes blackened steel a robust choice for constructions that experience dynamic loads or require superior load-bearing capabilities.

Corrosion resistance is another vital performance metric. The blackening process, which involves a controlled oxidation that forms a protective black oxide layer, can enhance the anti-corrosive properties of the steel. Studies indicate that blackened steel may exhibit improved resistance to corrosion compared to uncoated steel, especially in moderately corrosive environments. Additionally, the surface finish can affect friction characteristics; surface roughness measurements typically fall between 0.3 to 0.5 microns, making these tubes suitable for applications where sliding or fitting with other components is essential.

Lastly, the weldability of blackened steel tubes is crucial for structural integrity. According to engineering guidelines published by the Welding Institute, blackened steel can be welded using standard procedures, though it's vital to ensure proper cleaning to avoid weld defects. The presence of the oxide layer may require pre-welding treatments, but when done correctly, blackened steel tubes demonstrate consistent performance in both welded and bolted applications, proving their effectiveness in structural frameworks.

In the realm of blackened steel tube manufacturing, adherence to industry standards for durability is paramount. These standards are designed to ensure that products not only meet specific performance criteria but also withstand rigorous operational conditions. Companies often follow ASTM specifications and ISO certifications that dictate key characteristics such as tensile strength, corrosion resistance, and overall structural integrity. The evaluation of these attributes often involves both standardized testing methods and real-world stress assessments to verify that the tubes can endure the demands of their intended applications.

Furthermore, the manufacturing process itself plays a critical role in achieving the desired durability. Techniques such as precise welding, controlled heat treatment, and thorough surface preparation contribute to the overall quality of blackened steel tubes. Manufacturers are encouraged to leverage advanced technologies and quality control measures throughout the production cycle, from raw material selection to final inspections. By maintaining these rigorous standards and processes, companies not only enhance the performance of their blackened steel tubes but also establish a foundation of trust and reliability in the industry.

| Steel Tube Type | Diameter (inches) | Wall Thickness (gauge) | Yield Strength (psi) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Type A | 1.5 | 14 | 50,000 | Moderate | Furniture, Handrails |

| Type B | 2.0 | 12 | 65,000 | High | Structural Supports, Frames |

| Type C | 1.0 | 16 | 45,000 | Low | Decorative Elements, Art |

| Type D | 2.5 | 10 | 70,000 | Very High | Industrial Uses, Heavy Machinery |

In recent years, blackened steel tubes have gained increasing attention in the construction industry due to their outstanding durability and performance characteristics. According to a report by the American Institute of Steel Construction, steel tubes are preferred in various applications due to their high strength-to-weight ratio and resistance to environmental stresses.

Blackened steel, specifically, undergoes a process that enhances its corrosion resistance and aesthetic appeal, making it a top choice for both structural and decorative uses.

When considering the cost-benefit analysis of blackened steel tubes in construction projects, it becomes evident that their initial investment is often offset by their long-term benefits. A study by Research and Markets estimated that the lifespan of blackened steel components can be up to 50 years with minimal maintenance. This longevity reduces replacement costs and associated labor, contributing to the overall budget efficiency of construction projects. Furthermore, the enhanced surface treatment of blackened steel leads to decreased rust formation, which can lower insurance costs and improve the safety standards of completed structures.

The versatility of blackened steel tubes allows for their incorporation into various architectural designs while maintaining structural integrity. According to industry experts, the ability to customize dimensions and shapes gives engineers and architects more freedom in creating innovative designs without compromising the performance attributes. This flexibility, combined with their cost-effectiveness, positions blackened steel tubes as a smart choice for modern construction projects, aligning economic practicality with high-quality outcomes.