In today's industrial and manufacturing landscape, the Metal Tube Pipe has become an essential element. Its versatility is remarkable. It finds applications in various sectors, from construction to plumbing. Many industries rely on its strength and durability. Metal Tube Pipes are not just functional; they also offer aesthetic appeal.

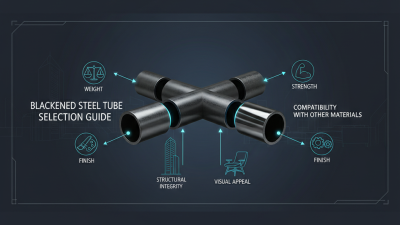

Despite their many benefits, some may overlook their potential. For example, the right choice of metal can impact overall project success. It requires thoughtful consideration. Taking shortcuts might lead to structural issues down the line. Choosing the right Metal Tube Pipe is crucial. Proper installation is equally important. These factors can make or break a project.

In this exploration, we delve into the top ten benefits of using Metal Tube Pipes. We will highlight specific applications that showcase their advantages. By the end, readers will appreciate the value these pipes bring. Through practical examples, the advantages will become clear. The Metal Tube Pipe is not just a component; it’s a game changer in various applications.

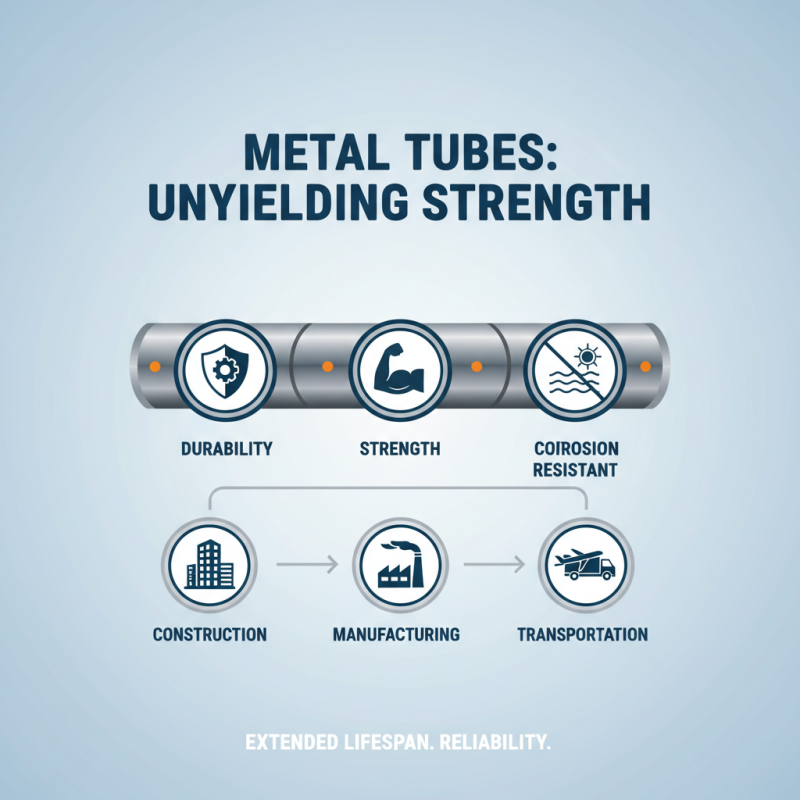

Metal tube pipes offer remarkable durability and strength, making them invaluable in various applications. These pipes resist wear and tear from environmental factors. Corrosion is a significant issue in many industries, but metal tubes can withstand such conditions, extending their lifespan. This resistance is crucial in construction, manufacturing, and transportation sectors.

In addition to their toughness, metal tube pipes are often lightweight. This combination of strength and reduced weight can enhance efficiency. However, while their performance is generally reliable, installation can be a challenge. Proper fitting and joining of components are essential to maximize their benefits. Misalignments during assembly can compromise strength over time, leading to potential failures.

Moreover, the inherent compatibility of metal with other materials permits a range of uses. They can be adapted for plumbing systems, structural frameworks, or even artistic designs. However, not all metal tubes are created equal. Evaluating each type’s properties is necessary for optimal performance. In some cases, opting for a cheaper alternative may result in lower quality. Thus, careful consideration is key when selecting metal tube pipes for any project.

Metal tube pipes are renowned for their enhanced corrosion resistance. This quality is vital in various environments. For instance, in marine settings, these pipes withstand saltwater exposure. Traditional materials often fail under such conditions, leading to costly replacements. However, metal tubes maintain their integrity longer, providing significant savings.

Different alloys offer specific corrosion-resistant properties. Stainless steel is popular for its robustness against rust. Other metals can be coated for even better protection. However, not all applications require high-end solutions. In some cases, budget constraints may lead to subpar choices. While cost-effective options exist, they may not stand the test of time.

Environmental factors also play a significant role. High humidity can accelerate corrosion, affecting even the best materials. In regions with extreme temperatures, thermal expansion can create weak points. Continually assessing the environment helps pinpoint potential issues. Implementing regular checks can prolong the lifespan of metal tube pipes. Misjudging conditions may result in premature failure, emphasizing the need for careful planning.

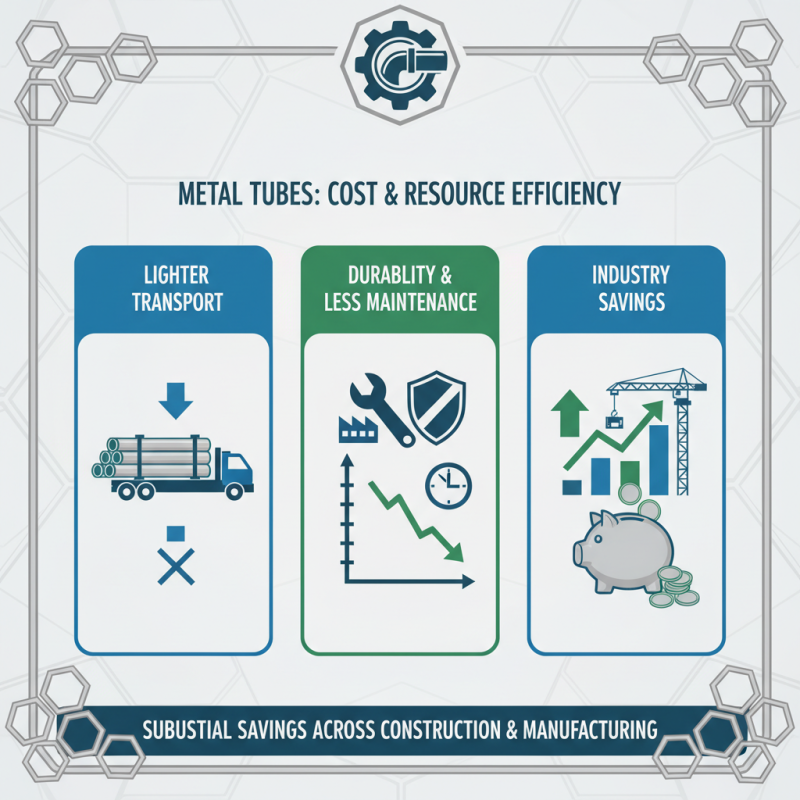

Metal tube pipes offer remarkable cost-effectiveness and efficient resource utilization across various industries. These pipes are often lighter than traditional materials, reducing transportation costs. Their durability means lower maintenance expenses over time. In sectors like construction and manufacturing, utilizing metal tubes can lead to substantial savings.

One important tip is to consider the specific needs of your project before choosing pipes. Assessing the required strength and corrosion resistance can lead to better resource allocation. Opting for the right specifications can save money in the long run.

Another factor to reflect on is fabrication waste. Metal tubes can be cut and shaped with precision, minimizing scrap material. This approach not only conserves resources but also supports sustainability efforts. Make sure to work with experienced professionals to ensure optimal designs that limit waste. This strategy can enhance overall project efficiency.

Metal tube pipes are incredibly versatile and useful in various structural and fluid applications. They offer strength and durability, making them ideal for construction projects. Architects and engineers often choose metal pipes for their resilience. These materials can withstand significant weight and pressure. This makes them a reliable choice in building frameworks.

In fluid applications, metal tubes provide an effective way to transport liquids and gases. Their robustness helps maintain the integrity of the contents. Metal pipes resist corrosion, which is a common issue in other materials. This feature makes them long-lasting in outdoor environments. However, the welding process can sometimes lead to weak joints. Ensuring proper technique and quality control is essential.

Moreover, metal tube pipes can be shaped into various sizes and configurations. This adaptability allows for use in numerous sectors, from automotive to aerospace. While metal pipes are not always the lightest option, their benefits often outweigh this drawback. Some design challenges may arise, especially with complex installations. Nevertheless, careful planning can overcome these issues.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Metal tubes are resistant to wear and corrosion, providing long-lasting performance. | Structural support, transport of fluids |

| Versatility | Can be used in a wide range of applications from construction to manufacturing. | Construction, automotive, aerospace |

| High Strength | Metal tubes can withstand high pressures and loads. | Pipelines, structural beams |

| Recyclability | Metal is recyclable, making it an environmentally friendly choice. | Construction, packaging |

| Temperature Resistance | Metal tubes maintain integrity at extreme temperatures. | Heat exchangers, aerospace |

| Cost-Effective | Lower long-term costs due to durability and low maintenance. | Manufacturing, construction |

| Aesthetics | Metal pipes can provide a sleek and modern appearance. | Architectural applications |

| Seamless Options | Seamless pipes reduce the risk of leaks. | Hydraulic systems, oil and gas |

| Easy to Work With | Can be easily fabricated, welded, and formed for various designs. | Manufacturing, custom projects |

The production of metal pipes has significant environmental implications. According to the World Steel Association, steel production is responsible for approximately 7-9% of global CO2 emissions. This highlights the need for sustainable practices in the industry. Many manufacturers are shifting to recycling processes. In fact, about 86% of steel is recycled. This reduces both energy use and carbon output.

Using metal tubes can be beneficial for eco-friendly projects. For instance, they can be reused in multiple applications. This enhances their lifespan and minimizes waste. By choosing recycled metal pipes, companies can lower their environmental footprint. This choice reflects a growing emphasis on sustainability, which influences consumer preferences.

Tip: Look for suppliers that prioritize sustainability in their manufacturing processes. It’s a productive way to support the environment. Another tip is to consider the lifecycle of the materials you use. Shorter lifecycles lead to more waste, while durable pipes ensure longevity. Remember, mindful choices can lead to significant environmental benefits.