In the world of construction and design, the importance of selecting the right materials cannot be overstated. As projects become more ambitious and the aesthetic demands rise, understanding the versatile application of Blackened Steel Tubes has become essential. According to industry expert James Carter, a veteran structural engineer and steel fabrication specialist, "Choosing the right Blackened Steel Tube is not just about functionality, but also about enhancing the visual appeal of your project." This highlights the dual role that Blackened Steel Tubes play—not only do they provide structural integrity, but they also contribute to the overall design ethos of a space.

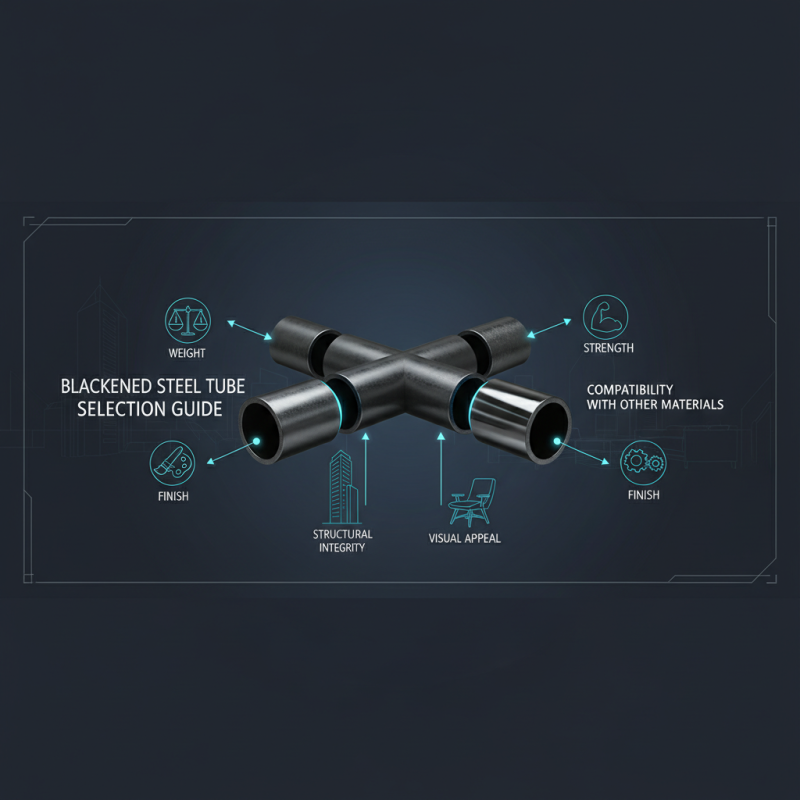

As we approach 2025, the landscape of building materials continues to evolve, presenting both challenges and opportunities for architects and builders alike. The decision-making process around Blackened Steel Tubes can be complex, influenced by factors such as weight, strength, finish, and compatibility with other materials. This guide aims to demystify the selection process, empowering project leaders to make informed choices that align with their design vision and structural requirements. Whether you are overseeing a high-rise construction or a custom furniture design, understanding the nuances of Blackened Steel Tubes will be integral to your project's success.

When selecting the right blackened steel tube for your project, several key factors come into play to ensure you make an informed decision. First and foremost, consider the intended application of the tube. Different projects may require varying levels of strength and durability. For instance, structural applications necessitate tubes that can withstand significant loads, while decorative uses may prioritize aesthetics over structural integrity.

Understanding the specific requirements of your project will help you narrow down your options effectively.

Another critical aspect to examine is the dimensions and specifications of the blackened steel tube. It's essential to determine the appropriate diameter, wall thickness, and length based on the project's design criteria. Additionally, evaluating the finish and coating of the steel can impact not only the appearance but also the corrosion resistance of the product. The quality of the blackened finish can affect both longevity and maintenance, emphasizing the importance of selecting a tube that meets your environmental and aesthetic needs. By carefully considering these factors, you can choose a blackened steel tube that aligns perfectly with the demands of your project.

When selecting blackened steel tubes for your project, it is imperative to understand the different grades and standards available in the market. Blackened steel tubes are often categorized based on their chemical composition, mechanical properties, and intended applications. Common grades include ASTM A513 and ASTM A500, which differ in terms of yield strength, tensile strength, and ductility. Choosing the appropriate grade ensures that the tubes will meet the specific performance requirements of your construction or manufacturing needs.

Additionally, the standards associated with blackened steel tubes, such as ANSI and ISO certifications, play a crucial role in ensuring quality and safety. These standards outline the manufacturing processes, testing methods, and quality control measures that must be adhered to in order to guarantee the integrity of the product. Familiarizing yourself with these standards allows you to make informed decisions on which tubes will provide the necessary durability and resistance to environmental factors for your project. Understanding these distinctions will not only optimize your selection process but also enhance the overall performance and longevity of your application.

When selecting blackened steel tubes for your project, evaluating the mechanical properties is critical to ensure optimal performance. Mechanical properties such as tensile strength, yield strength, and ductility play a fundamental role in determining how the material will behave under various stresses during usage. For instance, higher tensile strength is essential for applications that demand resistance to breaking under heavy loads, while adequate ductility is necessary to prevent brittle fractures, allowing the material to deform without failure.

Additionally, assessing the fatigue resistance of blackened steel tubes is vital for applications subjected to cyclic loading. Fatigue can lead to catastrophic failures over time, so choosing a tube with appropriate fatigue limits tailored to the specific operational environment enhances longevity and safety. Moreover, considering the hardness of the tube can also impact its wear resistance and overall durability, particularly in applications involving abrasive materials or environments. By thoroughly evaluating these mechanical properties, you can select the most suitable blackened steel tubes that align with your project requirements, ensuring both performance and reliability.

This bar chart illustrates the mechanical properties of various blackened steel tubes, including yield strength, tensile strength, and hardness. Understanding these properties is crucial for selecting the right material for your project.

When selecting blackened steel tubes for your project, understanding their corrosion resistance is paramount to ensuring longevity and durability. According to the Corrosion Technology Association, approximately 25% of all maintenance costs in various industries can be attributed to corrosion-related issues. This statistic underscores the importance of choosing materials that can withstand hostile environments. Blackened steel, often featuring a coating that enhances its ability to resist rust and oxidation, can be a strategic choice when assessing the environmental factors that may affect tube performance.

The effectiveness of blackened steel in resisting corrosion greatly depends on its protective finish and the conditions it is exposed to. A study by the National Association of Corrosion Engineers indicated that untreated blackened steel may corrode at rates up to 24 mils annually in a saline environment, while tubes treated with proper protective coatings can significantly reduce this rate. Moreover, understanding local climate conditions—such as humidity, temperature fluctuations, and exposure to salts—is crucial when determining the appropriateness of blackened steel tubes for your application. By thoroughly assessing these factors and relying on industry data, you can make informed decisions that enhance the longevity of your project while minimizing future maintenance costs.

| Tube Size (inches) | Wall Thickness (mm) | Weight (lbs/ft) | Corrosion Resistance Rating | Recommended Applications |

|---|---|---|---|---|

| 1.5 | 2.0 | 1.08 | Moderate | Structural Applications |

| 2.0 | 2.5 | 1.67 | High | Mechanical Components |

| 3.0 | 3.0 | 2.41 | Excellent | Industrial Equipment |

| 4.0 | 3.5 | 3.14 | Low | Piping Systems |

| 5.0 | 4.0 | 4.23 | Moderate | Construction Frames |

When budgeting for your project involving blackened steel tubes, it’s essential to understand the various cost components that will influence your overall expenditure. The price of raw materials can fluctuate based on market trends and availability, so it is prudent to keep an eye on steel market dynamics. In addition to material costs, consider other expenses such as transportation, fabrication, and installation, which can significantly impact your project's budget. Engaging with multiple suppliers may provide insight into competitive pricing and help identify the most cost-effective options.

Another important factor in your cost analysis is the potential for value engineering. This process involves evaluating different methods or materials that might reduce costs without sacrificing quality or structural integrity. For instance, sourcing locally may decrease shipping costs, while standardizing tube sizes can streamline fabrication processes and lessen waste. Additionally, consider the lifecycle costs of the blackened steel tubes. Investing slightly more upfront for higher-quality materials can result in savings over time through reduced maintenance and increased durability. By carefully analyzing these aspects, you can ensure that you budget effectively for the blackened steel tubes in your project.